Views: 222 Author: Wendy Publish Time: 2025-11-20 Origin: Site

Content Menu

● What are Aluminum Oxide Refractory Materials?

>> Key Properties of Aluminum Oxide Refractories

● The Significance of Fused Alumina in Refractory Manufacturing

>> Manufacturing Process of White Fused Alumina

● Aluminum Oxide Refractory Manufacturing Process

>> Bayer Process for Alumina Preparation

>> Forming and Sintering Refractory Products

● Top 10 Aluminum Oxide Refractory Manufacturers in China

>> 1. Dragon Abrasives Group Limited

>> 2. Zhengzhou Rongsheng Refractory Co., Limited

>> 3. Baoding Ningxin Group Co., Ltd.

>> 4. Shandong Hitech Material Co., Ltd.

>> 5. Gongyi Fengtai Refractory Abrasive Co., Ltd.

>> 6. Zibo Luzhong Refractory Co., Ltd.

>> 7. Henan Fireramo Industrial Co., Ltd.

>> 8. Hebei Xingshi New Material Technology Co., Ltd.

>> 9. Shandong Sinorefractory New Materials Co., Ltd.

>> 10. Qingdao Laurent New Materials Co., Ltd.

● Applications of Aluminum Oxide Refractory

● Market Trends and Innovations in Chinese Aluminum Oxide Refractory Industry

● How to Select a Reliable Aluminum Oxide Refractory Supplier

● FAQs: Aluminum Oxide Refractory in China

>> 1. What is aluminum oxide refractory mainly used for?

>> 2. How do Chinese suppliers ensure product quality?

>> 3. What are the key advantages of fused alumina in refractories?

>> 4. Can aluminum oxide refractories be customized?

>> 5. What trends influence the Chinese aluminum oxide refractory industry?

Aluminum oxide refractory materials are a cornerstone of modern high-temperature engineering, providing robust solutions for steelmaking, ceramics, glass, cement, and energy-intensive industries. Praised for their exceptional thermal stability, chemical resistance, and mechanical strength, aluminum oxide refractories are fundamental in maintaining operational efficiency and safety in industrial furnaces and reactors. As demand for advanced lining and insulation grows worldwide, China has distinguished itself as the leading supplier of aluminum oxide refractory products, blending innovation, scale, and customized service for global clients.[1][7][9][10]

This article details the top 10 aluminum oxide refractory manufacturers in China, each recognized for superior products and technical expertise. Dragon Abrasives Group Limited is presented as the industry leader, reflecting both market influence and technological advancement.

Aluminum oxide refractory products, also called alumina refractories, are ceramics composed primarily of Al₂O₃ (alumina), valued for their ability to withstand extreme heat, corrosive atmospheres, and mechanical abrasion. They are available in various forms, including dense and insulating bricks, castables, mortars, and pre-shaped components, tailored to specific application requirements.[3][4][7][1]

- High melting point: Typically above 2050°C

- Excellent chemical stability: Resistant to acids, alkalis, and slags

- Strong mechanical integrity: Maintains strength at elevated temperatures

- Low thermal conductivity: Supports efficient insulation

- Customization: Variable shapes, sizes, and physical properties per client needs

These essential properties make aluminum oxide refractories indispensable in furnaces, kilns, incinerators, and chemical reactors worldwide.[7]

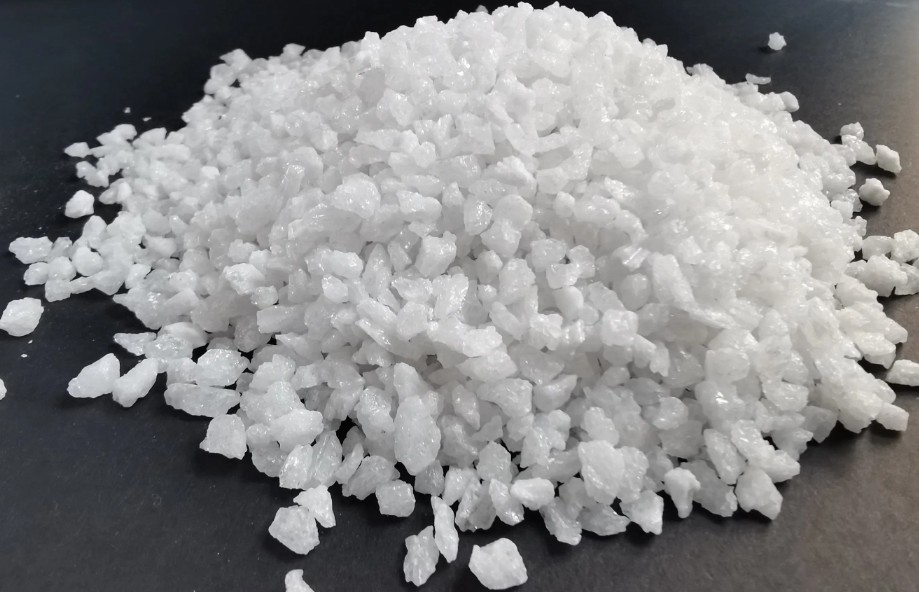

Fused alumina, produced by melting alumina at above 2000°C in electric arc furnaces, is considered the highest-quality raw material for demanding aluminum oxide refractory applications. The process generates highly pure crystals with uniform grain structure, minimal impurities, and elevated density, supporting outstanding durability and heat resistance.[5]

1. Selection of high-purity aluminum oxide: Only select ores or synthetic powders are used.

2. Electric arc furnace fusion: Heated past 2000°C, achieving a dense molten phase.

3. Crystallization and solidification: Slow cooling forms large, strong grains.

4. Crushing and grading: Material is ground and graded for each product's requirements.[5]

Fused alumina is particularly favored for steelworks, glassmelting tanks, and non-ferrous metal production, where chemical purity and thermal stability are critical.[11][12][5]

China's aluminum oxide refractory manufacturers employ advanced processes to ensure product purity, mechanical strength, and consistent quality.

The predominant method for refining alumina from bauxite is the Bayer process:

1. Crushing and grinding bauxite to increase surface area.[3]

2. Mixing with sodium hydroxide: Forms sodium aluminate solution under high temperature and pressure.

3. Impurity removal and alumina precipitation: Reduces impurities, yielding pure alumina after precipitation and washing.

4. Calcination: Heats the precipitate in kilns to drive off water and form refractory-grade alumina powder.[1][3]

- Shaping: Alumina powders are blended with chemical additives (binding agents) and shaped using dry pressing, slip casting, or extrusion.[4][6]

- Sintering or Fusing: Shaped “green bodies” are fired in kilns (1100–1400°C for standard products, >2000°C for fused alumina) to achieve ceramic bonding and maximize strength.[4][5]

- Finishing: Milling, grinding, and surface treatments enhance product performance, followed by rigorous quality control.[4]

Innovative manufacturers increasingly use recycled aluminum residues, blending them with adhesives, granulating, compressing, and sintering to create sustainable and efficient refractory products.[2]

Dragon Abrasives Group Limited leads China's aluminum oxide refractory sector, offering an extensive range of fused, brown, white, and black alumina products for both abrasive and refractory uses. The firm supports global customers in steel, metals, ceramics, and foundry industries with advanced custom solutions, ISO-certified production, and rapid international logistics.[13][14][15]

Strengths:

- Wide portfolio of aluminum oxide refractory bricks, monolithics, and castables

- Continuous R&D and strict quality controls

- Global presence and expert technical support

- Pioneering use of high-purity fused alumina[14][13]

Rongsheng is known for high-alumina refractory bricks, castables, mortars, and monolithic products. Their focus is on providing fast and flexible solutions for demanding steel, cement, and glass applications, with OEM/ODM customization.

Ningxin Group supplies premium refractory products including alumina bricks, insulation materials, and ceramic components. Their materials serve both high-temperature and corrosion-prone industrial settings.

Shandong Hitech is acclaimed for producing alumina slide gate plates, nozzle bricks, and refractory monolithics. The company also exports brown and white fused alumina for abrasive and refractory markets.

Fengtai specializes in aluminum oxide powders, fused alumina, and bauxite refractory ingredients, supplying to foundries, glass producers, and kiln operators globally.

Luzhong is trusted for high-density, high-alumina bricks and specialty castables. Their strengths include custom design, rapid production, and advanced engineering support.

Fireramo offers monolithic alu mina refractories and pre-shaped components for steel, non-ferrous and glass manufacture. Their integrated solutions are well regarded in high-heat applications.

Xingshi focuses on high-purity alumina and anti-acid refractory bricks for use in chemical, power, and metallurgy plants. The company's R&D drives energy-saving and corrosion-resistant product lines.

Sinorefractory serves continuous casting and furnace lining sectors with advanced alumina slide-gate products and refractory shapes, innovating for efficiency and longevity.

Laurent specializes in insulating bricks and high-performance castables made from premium fused alumina, with an emphasis on energy efficiency and custom design for both domestic and export markets.

Aluminum oxide refractories are engineered for a breadth of industrial applications, each demanding unique thermal and chemical tolerances:

- Steel and metallurgical furnaces: Alumina refractories form hearths, walls, and roof linings, resisting erosion by molten metal and slag.[7]

- Cement rotary kilns: These refractories endure abrasive rotary movement and maintain structure at elevated temperatures.

- Glass melting tanks: Purity and stability are critical in glass production, where alumina refractories ensure efficient melting and clarity.

- Petrochemical reactors: Reliable under rapid temperature swings and heavy chemical exposure.

- Waste incinerators and kilns: Survive repeated cycling, corrosion, and chemical attack.

Certain high-end products, such as fused alumina bricks, offer superior longevity, helping reduce maintenance cycles and improve operational reliability.[12][11][7]

The aluminum oxide refractory industry in China is responding to global demands for higher quality, greener manufacturing, and tailored solutions:

- Ultra-pure and shaped refractory bricks: Enhanced performance for critical process environments.

- Recycled aluminum residues: Greater utilization of sustainable materials and reduced waste.

- Digitization of production: AI and smart sensors optimize quality monitoring and resource efficiency.[2][4]

- Custom phase compositions: New formulas for elevated temperature and aggressive chemical requirements.

- Export markets: Strong logistics, certifications (ISO, CE, SGS), and technical documentation for international clients.

China's leading manufacturers are increasingly capable of supporting EU, US, and MENA clients, integrating local standards and certifying every supply chain phase.[10][16]

Industrial buyers should evaluate manufacturers by:

- Product portfolio breadth and depth

- Quality certifications and technical documentation

- R&D and customization capacity

- After-sales service and technical support

- Compliance with international standards (ISO 9001, CE, etc.)

Building partnerships with top Chinese suppliers such as Dragon Abrasives Group Limited ensures world-class technical solutions for high-value projects.

China's aluminum oxide refractory industry stands as a global powerhouse, continually advancing in technical innovation, product diversity, and international reach. Dragon Abrasives Group Limited exemplifies market leadership, offering a full suite of high-purity, performance-driven aluminum oxide refractory materials for clients across steel, cement, glass, and petrochemical sectors. The country's top manufacturers deliver superior product quality, rapid customization, and reliable service, empowering global industries to excel in both established and emerging applications.[9][10]

Aluminum oxide refractory is mainly used for lining high-temperature furnaces, kilns, and reactors in steelmaking, glass, cement, and ceramics industries due to its heat and corrosion resistance.[1][7]

Reputable Chinese suppliers utilize advanced manufacturing processes, strict quality control, international certifications (ISO, CE), and robust testing to guarantee consistency and performance.[16][10]

Fused alumina provides high purity, density, and mechanical strength, improving the longevity and reliability of refractory linings used in the most demanding industrial settings.[5]

Yes, most leading Chinese manufacturers offer OEM/ODM services for custom sizes, shapes, and compositions tailored to client-specific requirements and applications.[10]

Current trends include the integration of recycled materials, digital manufacturing, development of ultra-pure alumina grades, and strong export orientation to global markets.[2][4]

[1](https://www.ceramicsrefractories.saint-gobain.com/news-articles/aluminum-oxide-what-it-where-its-used)

[2](https://patents.google.com/patent/US20120289396A1/en)

[3](https://www.azom.com/article.aspx?ArticleID=52)

[4](https://www.rrmsb.com/post/refractory-manufacturing-the-complete-overview)

[5](https://honrel.com/white-fused-alumina-manufacturing-process/)

[6](https://www.firebirdref.com/how-are-alumina-oxide-ceramics-produced/)

[7](https://sanhuiabrasives.com/blog/alumina-refractory-cover.html)

[8](https://www.sciencedirect.com/topics/engineering/refractory-oxide)

[9](https://www.bloominglobal.com/media/detail/top-10-alumina-producers-in-china-2025)

[10](https://www.made-in-china.com/manufacturers/top-10-refractory.html)

[11](https://www.cumi-murugappa.com/emd/white-fused-alumina/)

[12](https://airblast.com/brown-fused-alumina/)

[13](https://www.stonecontact.com/suppliers-175691/dragon-abrasives-group-limited)

[14](http://www.caec-abr.com/en_index.html)

[15](http://www.abrasivesunion.com/companies/show_detail/6208)

[16](https://us.metoree.com/categories/6760/)

Top Pure Silicon Carbide Manufacturers and Suppliers in Russia

Top Pure Silicon Carbide Manufacturers and Suppliers in France

Top Pure Silicon Carbide Manufacturers and Suppliers in Arabia

Top Polishing Silicon Carbide Manufacturers and Suppliers in Thailand

Top Polishing Silicon Carbide Manufacturers and Suppliers in Turkey

Top Polishing Silicon Carbide Manufacturers and Suppliers in Vietnam

Top Polishing Silicon Carbide Manufacturers and Suppliers in South Korea

Top Polishing Silicon Carbide Manufacturers and Suppliers in Japan

Top Polishing Silicon Carbide Manufacturers and Suppliers in Poland

Top Polishing Silicon Carbide Manufacturers and Suppliers in Portugal