Abrasive Tools Product Category Description for Tianjin Jinda (Dragon Abrasives Group Limited)

Tianjin Jinda, operating under the brand Dragon Abrasives Group Limited, is a leading Abrasive Tools Manufacturer with over 40 years of expertise in the abrasives industry. Established in 2007 in Tianjin, China, the company specializes in a comprehensive range of abrasive tools and materials designed to meet the diverse needs of global industries. This detailed product category description explores the various types of abrasive tools offered by Dragon Abrasives, highlighting their features, materials, applications, performance benefits, and industry advantages.

Product Types of Abrasive Tools

Dragon Abrasives, a renowned Abrasive Tools Manufacturer, provides an extensive portfolio of abrasive tools, categorized primarily into bonded abrasives, coated abrasives, non-woven abrasives, and superabrasive tools. Each category is engineered to serve specific industrial functions with high precision and durability.

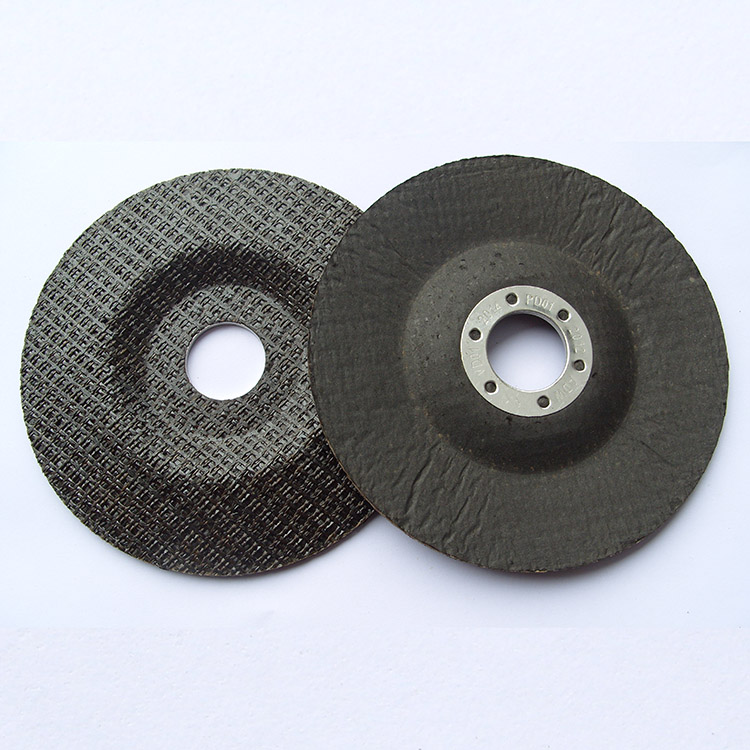

Bonded Abrasives

Bonded abrasives include grinding wheels, cutting wheels, sharpening stones, mounted points, and segments. These tools are typically manufactured using vitrified, resinoid, rubber, PVA, or PUR bonding agents, which provide structural integrity and optimal abrasive performance. Examples include:

- Vitrified Grinding Wheels: Known for their hardness and heat resistance, ideal for precision grinding.

- Cutting Wheels: Designed for efficient cutting of metals and other hard materials.

- Mounted Points: Small abrasive tools used for detailed grinding and finishing in tight spaces.

As a leading Abrasive Tools Manufacturer, Dragon Abrasives ensures these bonded abrasives meet stringent quality standards for industrial use.

Coated Abrasives

Coated abrasives consist of abrasive grains bonded to flexible backings such as cloth, paper, or polyester film. Dragon Abrasives offers a wide range of coated abrasive products, including:

- Abrasive cloth (rolls, sheets, belts, discs, flap discs, flap wheels)

- Abrasive paper (rolls, sheets, belts, fiber discs)

- Plastic discs and velours-backed discs (hook & loop and PSA types)

- Surface conditioning discs and sponge abrasive blocks

- Power abrasive discs for cleaning and stripping

These coated abrasives are versatile and widely used for sanding, grinding, polishing, and surface preparation. As a trusted Abrasive Tools Manufacturer, Dragon Abrasives tailors these products to meet diverse industrial demands.

Non-Woven Abrasives

Non-woven abrasives are manufactured from synthetic fibers bonded with abrasive grains, offering excellent surface conditioning and finishing capabilities. Products include rolls, sheets, pads, belts, flap wheels, flap discs, drums, convolute wheels, and surface conditioning discs. These tools are particularly effective for deburring, blending, and finishing applications where a softer touch is required.

Dragon Abrasives, as a professional Abrasive Tools Manufacturer, ensures that non-woven abrasives provide consistent quality and performance.

Superabrasive Tools

Dragon Abrasives also specializes in superabrasive tools that utilize synthetic diamond and cubic boron nitride (CBN) grits and powders. These tools are engineered for extreme hardness and wear resistance, suitable for high-precision grinding and cutting of hard materials such as ceramics, hardened steels, and composites. Superabrasive tools include:

- Diamond grinding wheels and saw blades

- Flexible diamond pads and diamond core drills

- CBN grinding wheels and honing stones

- Electrodeposited needle files

As a leading Abrasive Tools Manufacturer, Dragon Abrasives delivers superabrasive tools that meet the most demanding industrial standards.

Material Composition and Features

The abrasive tools from Dragon Abrasives are crafted from premium raw materials to ensure superior performance and longevity. Key abrasive grains used include:

- Aluminum Oxide: Available in brown, white, pink, and black variants, aluminum oxide is a versatile abrasive for grinding and finishing metals and alloys.

- Silicon Carbide: Offered in green and black forms, silicon carbide is sharp and hard, ideal for grinding non-ferrous metals, ceramics, and glass.

- Boron Carbide: Known for its extreme hardness, used in specialized abrasive applications.

- Zirconia Alumina and Single Crystal Aluminum Oxide: Provide enhanced toughness and cutting efficiency for heavy-duty grinding.

The bonding agents and backing materials are selected for durability, heat resistance, and optimal abrasive grain retention, ensuring consistent performance even under demanding conditions.

As a reputable Abrasive Tools Manufacturer, Dragon Abrasives rigorously tests all materials to maintain product excellence.

Applications and Industry Suitability

Dragon Abrasives' abrasive tools serve a broad spectrum of industries and applications, including:

- Metalworking: Grinding, cutting, deburring, and polishing of ferrous and non-ferrous metals.

- Automotive and Aerospace: Precision surface preparation, paint removal, and component finishing.

- Woodworking and Furniture Manufacturing: Sanding and finishing of wood surfaces.

- Electronics and Precision Engineering: Ultra-fine grinding and polishing of delicate components.

- Construction and Stone Fabrication :Cutting and polishing of concrete, granite, marble, and other stones.

Their abrasive tools enable manufacturers to achieve high precision, smooth finishes, and efficient material removal, enhancing product quality and operational productivity. As a globally recognized Abrasive Tools Manufacturer, Dragon Abrasives supports these industries with reliable, high-performance products.

Performance and Functional Advantages

The abrasive tools manufactured by Dragon Abrasives exhibit several key performance benefits:

- High Durability: Use of advanced bonding technologies and high-quality abrasive grains ensures long service life.

- Heat Resistance: Suitable for high-speed grinding and cutting without degradation.

- Consistent Abrasive Action: Uniform grain distribution and strong bonding prevent premature wear and loading.

- Versatility: Wide range of shapes, sizes, and grit options to match specific application needs.

- Precision: Superabrasives enable micron-level tolerances and superior surface finishes.

These performance characteristics make Dragon Abrasives a trusted Abrasive Tools Manufacturer for demanding industrial environments.

Industry Advantages and Expertise

With over four decades of experience in the abrasives sector, Dragon Abrasives leverages advanced production technologies and rigorous quality control to deliver products that meet international standards. The company's strengths include:

- Expertise: Senior experts with 40+ years of industry knowledge guide product development and customer support.

- Comprehensive Product Range: From raw abrasive grains to finished tools, Dragon Abrasives offers end-to-end solutions.

- Global Reach: Exporting worldwide, the company understands diverse market requirements and provides tailored solutions.

- Customer Support: Dedicated after-sales service ensures customers receive technical assistance and optimal product usage guidance.

- Innovation: Continual R&D efforts to improve abrasive materials and tooling technologies.

These advantages position Dragon Abrasives as a premier Abrasive Tools Manufacturer committed to quality, innovation, and customer satisfaction.

summary

Dragon Abrasives Group Limited from Tianjin is a distinguished Abrasive Tools Manufacturer offering an extensive selection of bonded, coated, non-woven, and superabrasive tools. Their products are crafted from high-grade materials such as aluminum oxide, silicon carbide, and boron carbide, designed for diverse industrial applications including metalworking, aerospace, woodworking, and precision engineering. With superior performance features like durability, heat resistance, and precision, combined with decades of industry expertise and global service capabilities, Dragon Abrasives stands out as a reliable partner for abrasive tool solutions worldwide. This makes them an ideal choice for businesses seeking high-quality abrasive tools to enhance manufacturing efficiency and product excellence.

With decades of experience in the industry, our quality is guaranteed. Come and contact us to purchase!