Views: 222 Author: Wendy Publish Time: 2025-11-20 Origin: Site

Content Menu

● Why Aluminum Oxide Raw Matters

● Understanding Aluminum Oxide Raw: Definitions and Types

>> What Is Aluminum Oxide Raw?

>> Key Types Produced in China

● The Manufacturing Process: From Bauxite To Alumina

● Why Choose Chinese Aluminum Oxide Raw Manufacturers?

● Top 10 Aluminum Oxide Raw Material Manufacturers in China

>> 1. Dragon Abrasives Group Limited

>>> Core Strengths:

>> 2. Zhengzhou Haixu Abrasives Co., Ltd.

>> 3. Aluminum Corporation of China Limited (CHALCO)

>> 5. China Hongqiao Group Limited

>> 6. Semicorex

>> 7. Avant AL

>> 8. Zibo Aotai New Material Technology Co., Ltd.

>> 9. Hebei Kenbin Technology Co., Ltd.

● Applications and Trends in the Aluminum Oxide Raw Industry

● The Fused Alumina Manufacturing Process

● Innovations and Quality Assurance

● How to Choose the Right Aluminum Oxide Raw Supplier

● Frequently Asked Questions (FAQ)

>> 1. What distinguishes white fused alumina from brown fused alumina?

>> 2. How do leading Chinese manufacturers maintain quality?

>> 3. Can aluminum oxide raw be tailored for specific customer needs?

>> 4. Which industries most benefit from industrial-grade aluminum oxide raw?

>> 5. What are the latest advancements in the aluminum oxide raw sector?

Aluminum oxide raw materials are foundational to numerous industries, particularly those involving abrasives, refractory products, ceramics, engineering materials, and advanced functional applications. China is globally recognized as the most important producer and exporter of aluminum oxide raw, offering high-purity, competitively priced, and technically optimized solutions for both large-scale industrial manufacturers and specialized niche markets. For buyers, sourcing from the top Chinese aluminum oxide manufacturers means unlocking value, custom technical support, and performance consistency.[9][10]

Aluminum oxide, widely known as alumina (Al₂O₃), ranks among the most valuable advanced ceramics and industrial materials. It is celebrated for:

- Extremely high hardness and mechanical strength

- Excellent chemical stability even in harsh environments

- Superb thermal resistance, making it ideal for use in refractories and kilns

- Electrical insulation properties

- Usability in powder, granular, lump, or sintered forms

The ability to access reliable, pure, and customizable aluminum oxide raw forms the backbone of global abrasive tools, refractory components, engineered ceramics, filtration technologies, and composite materials.[1][7]

Aluminum oxide raw refers to the unmodified, industrial-grade base material used as the starting point for further processing into fused alumina, tabular alumina, activated alumina, or synthetic sapphire. Its properties make it vital for abrasive and refractory production, and its versatility supports the ceramics, glass, metallurgy, and electronics sectors.[7]

- Brown Fused Alumina: Made from bauxite, notable for toughness and thermal stability, widely used in abrasive blasting and grinding.

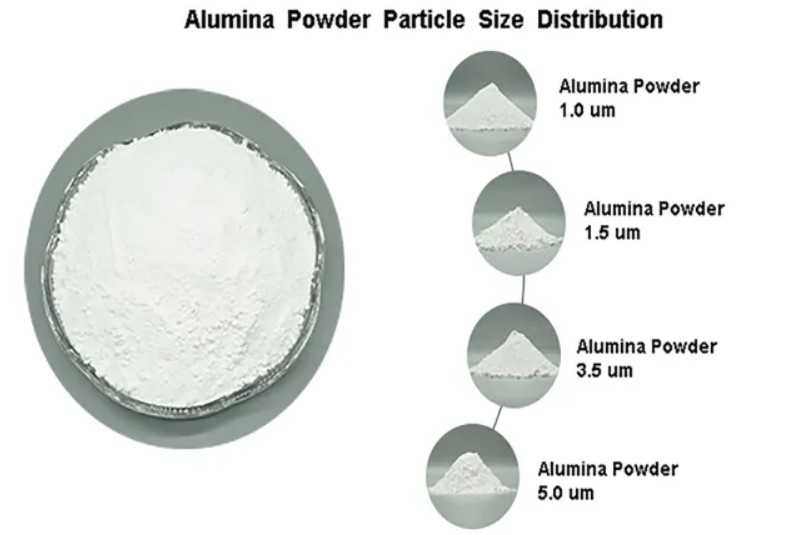

- White Fused Alumina: Higher in purity, produced from calcined alumina, ideal for high-precision grinding and advanced polishing.

- Tabular Alumina: Sintered at ultra-high temperatures, provides superior refractory performance.

- Activated Alumina: High surface area for catalysis, adsorption, and filtration applications.

- High-Purity Alumina: Used in electronics, LED, and advanced ceramics.

The most common industrial path for turning bauxite ore into aluminum oxide is the Bayer process, which includes several key stages:

1. Mining: Bauxite ore is mined using open-pit methods and is the primary aluminum-bearing mineral source.[2][5][6]

2. Refining: The Bayer process refines bauxite into alumina:

- Bauxite is washed, crushed, and mixed with hot sodium hydroxide solution;

- The process dissolves alumina, leaving iron oxides and impurities as “red mud”.[3][4]

- Aluminum hydroxide is precipitated and separated, then heated by calcination to yield pure alumina powder.[7]

3. Specialty Processing: For fused alumina, the calcined alumina is melted in electric arc furnaces, rapidly cooled, then crushed and classified into the desired grain sizes for customers.[3]

4. Customization: Particle size, purity, and morphological control are managed through processing parameters and post-processing techniques, allowing for specialty products tailored to demanding end uses.

China's aluminum oxide producers possess several global advantages:

- Scale and Depth: Home to dozens of leading integrated facilities with both upstream and downstream technical expertise.

- R&D and Innovation: Many leading brands support buyers with bespoke technical solutions, consistently innovating in grain size, crystal structure, purity, and contamination control.

- Export Reliability: Decades of logistics and documentation experience make Chinese companies trusted partners worldwide.

- Competitive Pricing: With abundant raw resources and optimized processes, both standard and custom grades of aluminum oxide raw are available at competitive prices.[10][9]

Dragon Abrasives Group Limited stands as one of the most reputable aluminum oxide raw suppliers and exporters in China. With headquarters and major manufacturing hubs in Zhengzhou, they manage brown fused alumina, white fused alumina, zirconia alumina, and silicon carbide facilities. Dragon emphasizes technical innovation, world-class quality management, and exceptional customer support across more than 60 export countries.[11]

- Comprehensive portfolio: from general abrasives to high-purity specialty grains

- Strong export service and logistical networks

- Adaptive R&D and custom solutions

- Customer-centric approach for long-term partnerships

Zhengzhou Haixu is a specialist in production and processing of white fused alumina, supplying high-purity, high-performance grains for polishing, coatings, ceramics, and precision abrasive industries. Their ISO-certified plants ensure international buyers receive precisely controlled, contaminant-free materials.[12]

CHALCO ranks as one of the largest aluminum oxide and aluminum producers globally. Their integrated production chain spans bauxite mining, refining, and finished alumina sales. Their industrial scale delivers unmatched supply stability for high-volume buyers, and their environmental initiatives set new industry benchmarks.[13][9]

A national leader in both alumina and aluminum alloys, Xinfa Group leverages mining, metallurgical, and chemical process expertise to produce high-quality aluminum oxide raw, supplying specialized inputs for smelters, ceramics, and refractory manufacturers.[9]

With end-to-end operations from bauxite mining to finished aluminum and alumina, Hongqiao delivers consistently high-quality aluminum oxide raw for industrial smelters, refractories, and advanced ceramics. Their scale and vertical integration guarantee secure supply at globally competitive prices.[9]

Semicorex is renowned for their advanced alumina ceramics and industrial alumina offerings. Their high-purity grades service electronics, semiconductor, and LED manufacturers needing demanding standards of performance.[14]

Avant AL provides premium-grade aluminum oxide raw and fused alumina, emphasizing purity, controlled particle size, and batch-to-batch consistency. Their materials fuel innovation in high-end engineered ceramics, coatings, and abrasive tools.[15]

Responsive to both large buyers and custom orders, Zibo Aotai covers brown and white fused alumina, tabular alumina, and specialty abrasives. Their engineering team works closely with global clients seeking rapid fulfillment for tailored solutions.[10]

Hebei Kenbin is a large-scale technical chemicals provider, incorporating aluminum oxide raw as a vital division. With industrial batch control, diverse formulations, and on-time delivery, they serve clients across abrasive, filtration, and high-temperature application sectors.[10]

Porocel Menjie Chem specializes in advanced activated alumina and catalyst carrier products. Their quality systems (including ISO and REACH certifications) appeal to international clients in the environmental, petrochemical, and process industries, making them a reliable partner for technical and functional alumina grades.[16]

Aluminum oxide raw is essential for:

- Abrasive tools and grinding wheels

- Sandblasting media for surface preparation

- High-temperature refractory bricks and castables

- Engineered ceramics for industrial automation

- Chemical catalysts, filtration media, and water treatment

- Metallurgical operations, glass, and electronics

- Sustainability: Leading producers continue to reduce water, energy, and emissions footprints in mining and chemical processing.

- Nanotechnology: Increasing focus on nano-alumina for advanced composite materials and electronics.

- Customization: End-users demand strictly specified purity, particle size, and phase composition, driving technical advances in process control.

The critical step that differentiates standard alumina from high-value fused alumina involves electric arc melting. Calcined alumina is introduced into arc furnaces, melted at temperatures above 2000°C, and then cooled. The resulting fused alumina offers enhanced hardness, toughness, and thermal resistance. These grains are then crushed and graded to meet the abrasive industry standards for quality, angularity, and cleanliness.[17][3]

Note: No image or video is embedded per your requirements.

Top Chinese manufacturers invest in:

- Advanced automated screening and classification

- On-site quality labs for real-time chemical and physical analysis

- Continuous R&D collaboration with end users

- Third-party lab verification and compliance with international safety and performance norms

This drives not only innovation but also global acceptance and repeat business.

When shortlisting a supplier, consider the following:

- Proven track record in export and technical support

- Quality certifications (ISO, REACH, etc.)

- Willingness to customize products and conduct third-party validation

- Consistent supply reliability, not just competitive pricing

- Strong after-sales and logistics support

Leading names such as Dragon Abrasives Group Limited, CHALCO, and Haixu consistently top global buyer lists for these reasons.

China's aluminum oxide raw material industry serves as the world's most dynamic hub for technical materials and advanced ceramics, led by top-tier enterprises such as Dragon Abrasives Group Limited. Backed by decades of expertise, industrial scale, and technical innovation, these manufacturers empower end-users to reach new performance standards, develop cutting-edge products, and secure reliable supply chains for global markets. As manufacturing demands evolve, China's leading producers are poised to keep delivering value-driven, high-quality, and environmentally responsible solutions for the future.[11][12][15][7][9]

White fused alumina is produced from pure calcined alumina and offers higher purity, hardness, and cutting precision, making it ideal for demanding applications like micro-abrasives and electronics. Brown fused alumina, made from bauxite, is more robust and widely used for general abrasive and blasting tools.[18][12]

Top Chinese manufacturers deploy integrated automated systems, in-house laboratories, and third-party testing for strict control over chemical composition, particle size, and mechanical properties, ensuring stable quality for each shipment.[14][16]

Yes. Trusted suppliers frequently develop custom batches with specified particle sizes, morphologies, or chemical purities, enabling clients to address unique requirements in high-performance applications.[12][11]

Abrasives, refractories, precision ceramics, chemical catalysis, filtration and water treatment, electronics, and glass manufacturing all depend on premium aluminum oxide raw for consistent, high-performance output.[7][14][9]

Recent advancements include more energy-efficient production, waste valorization (especially red mud), intelligent process automation, and the growing availability of nano-scale alumina for high-tech markets. Sustainability and customization are major trends.[1][7]

[1](https://www.ceramicsrefractories.saint-gobain.com/news-articles/aluminum-oxide-what-it-where-its-used)

[2](https://www.harboraluminum.com/en/aluminum-process)

[3](https://en.wikipedia.org/wiki/Bayer_process)

[4](https://www.tms.org/pubs/books/4062.chapter2.pdf)

[5](https://www.ltcoatingline.com/resources/aluminum-production-and-manufacturing-process-explained.html)

[6](https://www.thyssenkrupp-materials.co.uk/how-is-aluminum-made)

[7](https://www.aluminum.org/alumina-refining-101)

[8](https://www.globallcadataaccess.org/aluminum-oxide-sinter-process)

[9](https://www.mordorintelligence.com/industry-reports/aluminum-oxide-market/companies)

[10](https://www.made-in-china.com/manufacturers/aluminium-oxide.html)

[11](http://www.caec-abr.com/en_index.html)

[12](https://whitecorundum.com/about-us/)

[13](https://www.imarcgroup.com/top-aluminum-oxide-companies)

[14](https://www.semicorex.com/alumina-al2o3-)

[15](https://www.avant-al.com/aluminum-oxide/)

[16](https://www.menjiechem.com/application/porocel-activated-alumina)

[17](https://www.youtube.com/watch?v=qLJlskMflSA)

[18](https://www.youtube.com/watch?v=n8I2zImSfVs)

Top Pure Silicon Carbide Manufacturers and Suppliers in Russia

Top Pure Silicon Carbide Manufacturers and Suppliers in France

Top Pure Silicon Carbide Manufacturers and Suppliers in Arabia

Top Polishing Silicon Carbide Manufacturers and Suppliers in Thailand

Top Polishing Silicon Carbide Manufacturers and Suppliers in Turkey

Top Polishing Silicon Carbide Manufacturers and Suppliers in Vietnam

Top Polishing Silicon Carbide Manufacturers and Suppliers in South Korea

Top Polishing Silicon Carbide Manufacturers and Suppliers in Japan

Top Polishing Silicon Carbide Manufacturers and Suppliers in Poland

Top Polishing Silicon Carbide Manufacturers and Suppliers in Portugal