Views: 222 Author: Leah Publish Time: 2025-12-09 Origin: Site

Content Menu

● Why Silicon Carbide is Ideal for Sandblasting

● Spanish Market Overview for Silicon Carbide Sandblasting

● Core Silicon Carbide Production in Spain

>> Navarro SiC – Domestic Silicon Carbide Producer

● Spanish Abrasive and Sandblasting Specialists

>> Arcillas Refractarias S.A. (Arciresa)

>> ABRAMASTER – Coated Abrasives Using SiC

● Sandblasting Equipment and Service Providers in Spain

>> Other Blasting‑Related Players

● Key Market Trends Influencing Silicon Carbide Demand

>> Higher Performance and Stricter Standards

>> Sustainability and Cost Efficiency

● How Dragon Abrasives Supports Spanish and Global Buyers

>> Customized Silicon Carbide Sandblasting Media

>> OEM, Private‑Label, and Technical Support

● Selecting the Right Silicon Carbide Sandblasting Partner

>> Product Quality and Traceability

>> Application Knowledge and Support

>> Logistics, Inventory, and Responsiveness

>> Regulatory Compliance and Sustainability

● Typical Applications for Silicon Carbide Sandblasting

>> Surface Preparation for Coating and Bonding

>> Cleaning and Maintenance of Industrial Components

>> Decorative and Functional Texturing

● Integrated Spanish Silicon Carbide Sandblasting Ecosystem

● FAQ

>> 1. Why choose silicon carbide over other blasting media?

>> 2. Are there many Silicon Carbide Sandblasting Manufacturers and Suppliers in Spain?

>> 3. Which industries in Spain use silicon carbide sandblasting most intensively?

>> 4. How can buyers evaluate the quality of silicon carbide sandblasting media?

>> 5. What role can Dragon Abrasives play for Spanish customers?

Spain has become one of the most dynamic European markets for advanced abrasives, especially Silicon Carbide Sandblasting media used in automotive, construction, aerospace, and precision engineering. As industries demand cleaner surfaces, tighter tolerances, and higher productivity, buyers pay much closer attention to how Silicon Carbide Sandblasting Manufacturers and Suppliers can support their long‑term production goals.[1][2]

For international customers, particularly those sourcing from Asia, understanding Spain's network of silicon carbide producers, abrasive manufacturers, and blasting‑service providers is essential to building a resilient and efficient supply chain. Dragon Abrasives Group Limited, as a professional Chinese producer and exporter, positions itself as a strategic partner that complements Spanish Silicon Carbide Sandblasting Manufacturers and Suppliers with customized, high‑quality silicon carbide solutions.[3]

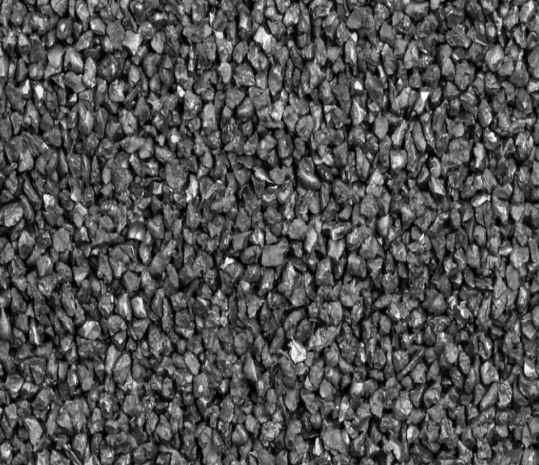

Silicon carbide is one of the hardest conventional abrasive materials, with a sharp, angular grain that delivers very aggressive cutting action on metals, stone, glass, and advanced composites. This exceptional hardness allows silicon carbide to remove coatings, rust, and scale quickly while creating controlled surface roughness for superior coating or adhesive bonding.[4][3]

Unlike many softer abrasives, silicon carbide maintains its cutting edges for longer, which means lower media consumption and more consistent blasting results over time. Its high thermal and mechanical stability also makes it suitable for high‑pressure blast systems, turbine blast machines, and automated cabinets where both performance and durability are crucial.[5][1]

Another key advantage promoted by Silicon Carbide Sandblasting Manufacturers and Suppliers is the material's purity and narrow particle‑size distribution, which translate into predictable surface profiles and reduced risk of contamination on stainless steel or non‑ferrous substrates. This predictability is particularly valuable in sectors such as aerospace, offshore structures, and critical machinery components, where surface preparation is closely tied to safety and performance.[3][4]

Spain combines a strong industrial base with ongoing investments in infrastructure, shipyards, metal fabrication, and automotive clusters, all of which rely on efficient surface‑preparation processes. As a result, the demand for high‑performance abrasives has expanded, and Silicon Carbide Sandblasting Manufacturers and Suppliers now play a central role in many Spanish value chains.[6][1]

Market studies on Europe's sandblasting media and silicon carbide sectors show steady growth, with silicon carbide gaining share thanks to its high cutting efficiency and long life. The adoption of automated blast cabinets, robotic blasting cells, and integrated dust‑collection systems across Spain further encourages the use of premium media such as silicon carbide, which helps maximize throughput and minimize downtime.[2][1]

In addition to end‑users, the Spanish market features specialized distributors, fabricators, and blasting contractors who influence which Silicon Carbide Sandblasting Manufacturers and Suppliers are selected for different applications. Their feedback and performance requirements push suppliers to offer more consistent quality, better packaging options, and tailored technical support.[7][8]

Navarro SiC stands out as Spain's main dedicated producer of silicon carbide, operating modern facilities that manufacture a wide range of SiC grains and powders. With decades of experience and a strong export orientation, Navarro SiC supplies silicon carbide to abrasives, refractories, metallurgical users, and specialized high‑tech sectors.[9][10]

For Silicon Carbide Sandblasting Manufacturers and Suppliers, Navarro SiC is a strategic upstream partner because it can deliver high‑purity, tightly graded grains from millimetric sizes to very fine powders. Its ability to control parameters such as free silica content, magnetic impurities, and bulk density supports the production of consistent and reliable silicon carbide sandblasting media.[10][9]

This domestic production capacity offers Spanish abrasive converters and service providers a level of security and flexibility that many other markets do not enjoy. While global supply chains remain important, having a local silicon carbide producer reduces lead times, facilitates technical cooperation, and enables rapid adaptation to new industrial requirements.[9][10]

Beyond primary silicon carbide production, Spain hosts a range of abrasive manufacturers and surface‑treatment specialists that convert SiC into finished products or use it in advanced blasting services. These companies form a crucial part of the broader ecosystem of Silicon Carbide Sandblasting Manufacturers and Suppliers.[11][7]

Arcillas Refractarias S.A., often referred to as Arciresa, offers a portfolio that includes silicon carbide abrasives used in grinding, cutting, and blasting operations. By combining silicon carbide with other materials such as corundum and slag, Arciresa can serve foundries, steel plants, and metalworking companies that need tailored abrasive solutions for both preparation and finishing.[12]

Abrasteel Abrasivos is another example of a Spanish company that produces and supplies abrasive materials, including black silicon carbide. Its products are promoted for use on aluminum, bronze, brass, ceramics, and various organic materials, making them suitable for both sandblasting and precision finishing tasks where fast cutting and clean surfaces are required.[7]

ABRAMASTER specializes in coated abrasives and uses silicon carbide, zirconia, and ceramic grain in discs, belts, and flexible products that frequently complement blasting steps in industrial finishing lines. Because silicon carbide offers a very sharp and friable cutting action, it is favored in coated abrasives for applications involving non‑ferrous metals, stone, glass, and composites.[13]

Together, these companies demonstrate how Silicon Carbide Sandblasting Manufacturers and Suppliers in Spain rely on both primary SiC production and downstream converters to deliver customized abrasive products across many sectors.[7]

A complete silicon carbide sandblasting ecosystem requires more than abrasives alone; it also depends on equipment manufacturers and blasting contractors that can apply the media efficiently and safely. In Spain, several companies specialize in sandblasting systems, blast rooms, cabinets, and contract services that make intensive use of silicon carbide and other media.[14][6]

Ipar‑Blast S.L. offers precision blasting services, focusing on controlled removal of rust, scale, and coatings, as well as surface texturing for industrial customers. By using high‑quality media and modern blasting technology, companies like Ipar‑Blast help end‑users understand the real performance advantages associated with premium silicon carbide products.[14]

Couto Industrial, known through the ABShot brand, designs and supplies sandblasting machines, cabinets, and systems capable of handling a wide variety of abrasives, including silicon carbide. Its solutions emphasize productivity, dust control, and operator safety, which are key when integrating silicon carbide into continuous or automated blasting lines.[6][14]

In addition, distributors and service‑oriented firms such as Abraservice Ibérica or Abrasivos Salinas contribute to the Spanish market by supplying abrasives, transforming materials, and advising customers on optimal media selection. These organizations help connect end‑users with the most suitable Silicon Carbide Sandblasting Manufacturers and Suppliers for each project or industry segment.[14][7]

Several market and technology trends are driving demand for silicon carbide and shaping the strategies of Silicon Carbide Sandblasting Manufacturers and Suppliers in Spain.[1]

The spread of automated blast cabinets, robotic blasting cells, and fully integrated finishing lines requires abrasives that behave consistently over long production runs. Silicon carbide is particularly suited to such environments because it provides stable cutting performance, predictable wear, and uniform surface profiles that can be closely controlled and monitored.[5][1]

Modern coating systems, thermal‑spray layers, and structural adhesives often come with strict surface‑preparation specifications, including target roughness ranges and cleanliness levels. Silicon Carbide Sandblasting Manufacturers and Suppliers can help customers meet these standards by offering SiC media with tightly controlled particle‑size distributions and documented performance characteristics.[8][4]

European buyers pay increasing attention to environmental impacts, waste volumes, and overall process efficiency in blasting operations. Because silicon carbide tends to last longer than many conventional mineral abrasives, it can reduce total media consumption, disposal needs, and energy use per treated surface area, contributing to both sustainability and cost efficiency.[2][8]

These trends reinforce the role of silicon carbide as a premium choice, especially in demanding or high‑volume applications where the added value of better performance outweighs higher unit media costs.[1]

Dragon Abrasives Group Limited, based in China, is a professional producer and exporter of high‑quality abrasives and refractories, including a wide portfolio of silicon carbide products. (Corporate positioning statement.) By working closely with distributors and end‑users in Europe, the company can complement Spanish Silicon Carbide Sandblasting Manufacturers and Suppliers with competitive pricing, flexible logistics, and tailor‑made media specifications. (Corporate positioning statement.)

Dragon Abrasives offers silicon carbide sandblasting media in multiple grades, color types, and particle‑size ranges to match different blasting processes and substrates. (Corporate capability statement.) Customers can select sharp, angular grains for aggressive cleaning, or more carefully graded media for precise surface profiling in preparation for coatings, plating, or bonding. (Corporate capability statement.)

These Silicon Carbide Sandblasting Manufacturers and Suppliers services extend to custom blends, bulk densities, and packaging formats—such as small bags, palletized sacks, and jumbo bags—ensuring that each buyer receives media optimized for its specific equipment and throughput requirements. (Corporate capability statement.)

Dragon Abrasives also supports OEM and private‑label arrangements, enabling Spanish distributors and integrators to strengthen their own brands while relying on a stable silicon carbide manufacturing base. (Corporate capability statement.) Technical teams can assist with media selection, trial runs, and troubleshooting, ensuring that silicon carbide sandblasting media performs reliably in real‑world blasting cabinets, rooms, and field operations. (Corporate capability statement.)

This combination of customization, branding flexibility, and technical guidance makes the company a valuable partner to both local Spanish Silicon Carbide Sandblasting Manufacturers and Suppliers and direct industrial users.

Choosing suitable Silicon Carbide Sandblasting Manufacturers and Suppliers is a strategic decision that affects product quality, production efficiency, and long‑term operating costs. Several criteria can help buyers qualify and compare potential partners.[15][16]

Reliable suppliers provide detailed documentation on chemical composition, particle‑size distribution, hardness, and bulk density for each silicon carbide product. Certificates of analysis, batch traceability, and regular lab testing all indicate a strong quality‑management system capable of supporting demanding industrial applications.[10][9]

Top Silicon Carbide Sandblasting Manufacturers and Suppliers do more than sell media; they help customers determine the right grain size, operating pressure, stand‑off distance, and nozzle design for specific materials and processes. Their recommendations can significantly improve blasting speed, surface uniformity, and media life, particularly in challenging applications involving stainless steel, aluminum, or highly alloyed components.[16][15]

Consistent supply is essential in high‑volume blasting operations, where production lines depend on a continuous flow of abrasive. Buyers should evaluate suppliers' stock levels in Europe, delivery times, packaging options, and flexibility in responding to urgent orders or special grade requirements.[2][7]

Since blasting operations are subject to regulations on dust emissions, worker safety, and environmental impact, Silicon Carbide Sandblasting Manufacturers and Suppliers must understand and support compliance with European standards. This includes providing safety data sheets, guidance on dust collection and media recycling, and options for more durable or reusable abrasive solutions.[8][2]

Silicon carbide sandblasting media is used wherever tough substrates, demanding cleanliness requirements, or precise surface profiles make conventional sand or softer abrasives insufficient. Silicon Carbide Sandblasting Manufacturers and Suppliers regularly support a broad set of applications.[4][3]

In industries such as automotive, marine, and structural steel, silicon carbide sandblasting is used to remove old coatings, rust, and contaminants while generating a defined anchor profile for new paints, powders, or thermal‑spray layers. The aggressive cutting ability of silicon carbide shortens blasting time and improves coating adhesion on critical components and structures.[8][1]

Foundries, forging shops, and machine builders often use silicon carbide to clean castings, dies, molds, and tooling that accumulate tenacious scales or residues. Because silicon carbide can remove stubborn deposits without excessive rounding of edges, it helps maintain dimensional accuracy and prolong the life of expensive equipment.[15][16]

Silicon carbide sandblasting also plays a role in decorative and functional texturing of stone, glass, ceramics, and composite surfaces. Fine silicon carbide grits enable controlled matte finishes, frosting, and micro‑roughness that improve both aesthetics and functional properties such as slip resistance or bonding strength.[4][15]

Spain's silicon carbide sandblasting landscape combines raw‑material production, abrasive conversion, equipment design, and field services into a cohesive ecosystem. Primary producers like Navarro SiC supply high‑quality SiC grains to abrasive manufacturers and converters, which in turn serve blasting contractors, distributors, and end‑users.[9][7]

Equipment makers and service companies, such as Couto Industrial (ABShot) and Ipar‑Blast S.L., then ensure that silicon carbide sandblasting media is applied with maximum efficiency and safety in real industrial environments. By collaborating with international partners like Dragon Abrasives, Spanish Silicon Carbide Sandblasting Manufacturers and Suppliers can offer customers a unique blend of local expertise and global manufacturing capacity.[6][14]

This integrated approach means that buyers looking for silicon carbide sandblasting solutions in Spain can access everything they need—from raw SiC material and precision‑graded media to turn‑key blasting systems and outsourced blasting services—through a network of complementary providers.[7]

Spain has established itself as an important hub for silicon carbide abrasives, supported by domestic SiC production, specialized abrasive manufacturers, advanced sandblasting equipment builders, and experienced blasting contractors. Growing demand for high‑performance, efficient, and environmentally responsible surface‑preparation technologies across automotive, construction, metal fabrication, and infrastructure projects is steadily increasing the role of Silicon Carbide Sandblasting Manufacturers and Suppliers in the Spanish market.[1][9]

By combining the strengths of Spanish producers and service providers with international partners such as Dragon Abrasives Group Limited, buyers can design robust and flexible sourcing strategies for silicon carbide sandblasting media and related products. This collaborative model offers stable quality, competitive costs, and tailored technical support, allowing end‑users to fully exploit the advantages of silicon carbide in both conventional and highly specialized blasting applications.

Silicon carbide provides much higher hardness and sharper cutting edges than many common mineral abrasives, resulting in faster material removal and more precise surface roughness. It also tends to last longer under demanding conditions, which can reduce media consumption and overall blasting costs in high‑volume industrial operations.[5][4]

Spain has a complete silicon carbide sandblasting ecosystem that includes a primary SiC producer, abrasive manufacturers, converters, distributors, equipment makers, and blasting contractors. This network enables buyers to source everything from raw silicon carbide grains to fully integrated sandblasting solutions from Spanish and international partners.[9][7]

The most intensive users include automotive and component manufacturers, metal fabrication and construction, shipyards, and industrial machinery builders. In addition, high‑precision sectors such as aerospace, energy, and advanced manufacturing utilize silicon carbide sandblasting where strict surface‑preparation standards and high reliability are required.[3][1]

Buyers should request detailed technical data sheets and certificates of analysis showing chemical composition, particle‑size distribution, and key physical properties. Test trials in actual blasting equipment, combined with supplier audits and reviews of quality‑management systems, give further assurance that Silicon Carbide Sandblasting Manufacturers and Suppliers can deliver consistent performance.[10][9]

Dragon Abrasives can supplement local supply by providing customized silicon carbide sandblasting media, flexible packaging and private‑label solutions, and technical support for process optimization. (Corporate capability statement.) By partnering with Spanish distributors and end‑users, the company helps ensure stable, cost‑effective access to high‑quality silicon carbide products that fit local market needs. (Corporate capability statement.)

[1](https://www.marketdataforecast.com/market-reports/europe-sandblasting-media-market)

[2](https://www.verifiedmarketresearch.com/product/abrasive-blasting-media-market/)

[3](https://www.businessmarketinsights.com/reports/europe-silicon-carbide-market)

[4](https://surfaceprep.com/product-category/specialty-materials/silicon-carbide/)

[5](https://www.factmr.com/report/silicon-carbide-market)

[6](https://www.grandviewresearch.com/horizon/outlook/sand-blasting-machines-market/spain)

[7](https://ensun.io/search/abrasive/spain)

[8](https://www.futuremarketinsights.com/reports/sandblasting-media-market)

[9](https://www.navarrosic.com/index.php/en/)

[10](https://www.navarrosic.com/index.php/en/company)

[11](https://sg.kompass.com/z/es/a/silicon-carbide-products/31760/)

[12](http://www.arciresa.es/abrasive-silicon-carbide.html)

[13](https://www.abramaster.com/en/productos/abrasivos-flexibles)

[14](https://ensun.io/search/sandblasting/spain)

[15](https://sanhuiabrasives.com/blog/silicon-carbide-sandblasting-media.html)

[16](https://canabrasive.com/blog/top-silicon-carbide-manufacturers-in-2025.html)

Top Pure Silicon Carbide Manufacturers and Suppliers in Russia

Top Pure Silicon Carbide Manufacturers and Suppliers in France

Top Pure Silicon Carbide Manufacturers and Suppliers in Arabia

Top Polishing Silicon Carbide Manufacturers and Suppliers in Thailand

Top Polishing Silicon Carbide Manufacturers and Suppliers in Turkey

Top Polishing Silicon Carbide Manufacturers and Suppliers in Vietnam

Top Polishing Silicon Carbide Manufacturers and Suppliers in South Korea

Top Polishing Silicon Carbide Manufacturers and Suppliers in Japan

Top Polishing Silicon Carbide Manufacturers and Suppliers in Poland

Top Polishing Silicon Carbide Manufacturers and Suppliers in Portugal