Views: 222 Author: Lake Publish Time: 2025-04-25 Origin: Site

Content Menu

● Introduction to DIY Sandblasting Media

● What Is Sandblasting Media and Why Does It Matter?

● Common DIY Sandblasting Media Options

>> Play Sand

>> Baking Soda (Sodium Bicarbonate)

● Factors to Consider When Choosing DIY Sandblasting Media

● Safety Precautions for DIY Sandblasting

● How to Prepare and Use DIY Sandblasting Media

● Environmental Impact and Disposal

● FAQ

>> 1. What is the safest DIY sandblasting media?

>> 2. Can I use play sand for sandblasting at home?

>> 3. How do I reduce dust when sandblasting at home?

>> 4. Is crushed glass a good DIY sandblasting media?

>> 5. Can I make walnut shell media at home?

Sandblasting is an effective technique for cleaning, restoring, and preparing surfaces by propelling abrasive particles at high speed. While professional sandblasting uses specialized media and equipment, many DIY enthusiasts seek affordable, accessible, and safe alternatives for home projects. Choosing the right DIY sandblasting media is essential to achieve good results without damaging the substrate or compromising safety. This comprehensive guide explores various materials you can use as DIY sandblasting media at home, their properties, advantages, limitations, and safety considerations.

Sandblasting media are the abrasive particles that remove rust, paint, dirt, and other surface contaminants when propelled at high velocity. Commercial media are often specialized and regulated, but DIY sandblasting can be done using readily available materials, provided safety and environmental precautions are observed.

The right media choice balances cleaning effectiveness, substrate protection, cost, availability, and safety.

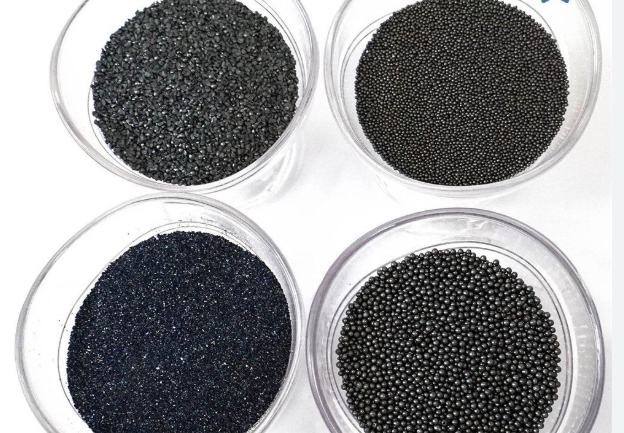

Sandblasting media vary in hardness, shape, size, and chemical composition. These factors determine:

- How aggressively the media removes material

- The surface finish and profile it creates

- Dust generation and health risks

- Environmental impact and ease of disposal

- Cost and reusability

Using inappropriate media can damage the surface, create hazardous dust, or produce poor results.

- Description: Readily available fine sand sold for children's play areas.

- Pros: Cheap and easy to find.

- Cons: Contains silica, which poses serious health risks (silicosis) when inhaled. Not recommended for sandblasting due to toxicity and regulatory restrictions.

- Description: Recycled glass crushed into abrasive particles.

- Pros: Eco-friendly, non-toxic, effective for rust and paint removal.

- Cons: Can be abrasive and may require protective equipment. Usually purchased rather than DIY sourced.

- Description: Soft, non-abrasive media made from common baking soda.

- Pros: Gentle on surfaces, non-toxic, biodegradable, easy to clean up.

- Cons: Slower removal rate, not suitable for heavy rust or thick coatings.

- DIY Use: Easily sourced from grocery stores, suitable for delicate surfaces.

- Description: Crushed walnut shells used as a soft organic abrasive.

- Pros: Biodegradable, gentle, effective on wood and delicate metals.

- Cons: Not typically DIY sourced; usually purchased.

- DIY Potential: Possible to crush shells at home but requires equipment.

- Description: Ground corn cobs used as a soft abrasive.

- Pros: Biodegradable, absorbent, gentle on surfaces.

- Cons: Less aggressive, usually purchased.

- DIY Potential: Limited for home preparation.

- Description: Hard metallic abrasives used for heavy-duty cleaning.

- Pros: Effective for rust and scale removal.

- Cons: Not DIY; requires specialized equipment and safety measures.

- Description: Hard, sharp abrasive used industrially.

- Pros: Durable, fast cutting.

- Cons: Not DIY; requires purchase and safety precautions.

- Rice hulls, ground coffee, salt, sugar: Occasionally experimented with but generally ineffective or damaging.

- Avoid materials containing silica or toxic substances.

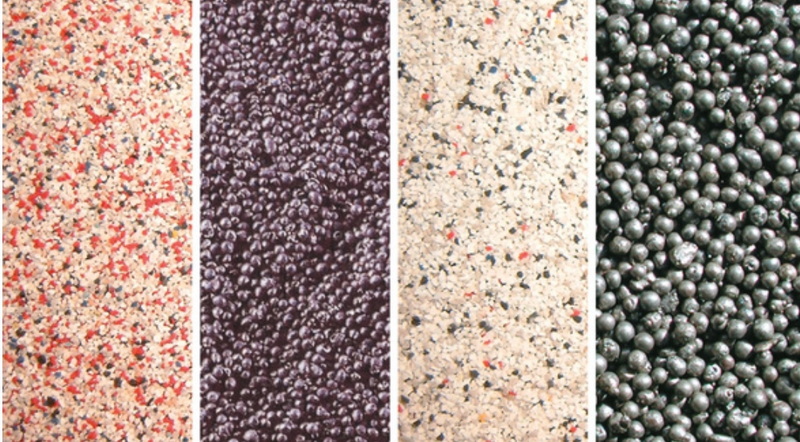

- Surface Type and Sensitivity: Soft materials like wood require gentle media; metals tolerate harder abrasives.

- Rust or Coating Thickness: Heavy rust requires aggressive media; light cleaning suits softer abrasives.

- Health and Safety: Avoid silica-containing media; ensure dust control and PPE use.

- Environmental Impact: Prefer biodegradable, non-toxic options.

- Cost and Availability: Use readily available, affordable media for DIY projects.

- Equipment Compatibility: Media size and hardness must suit your blasting equipment.

- Always wear respiratory protection (N95 or better) to avoid inhaling dust.

- Use eye protection and gloves to prevent injury.

- Blast in well-ventilated or outdoor areas to reduce dust exposure.

- Avoid using silica sand due to severe health risks.

- Use dust collection systems or wet blasting to minimize airborne particles.

- Dispose of spent media responsibly.

- For baking soda blasting, use fine, dry baking soda powder.

- Crushed glass can be purchased or made by crushing clean glass bottles (wear protective gear).

- For walnut shells or corn cob grit, purchase from suppliers or carefully crush shells with a hammer and sieve.

- Use appropriate blasting equipment with pressure settings adjusted for media hardness.

- Test media on a small area before full application to assess surface impact.

- Biodegradable media like baking soda, walnut shells, and corn cob grit minimize environmental harm.

- Crushed glass and aluminum oxide require proper disposal to avoid pollution.

- Avoid dumping spent media in drains or soil; follow local regulations.

- Wet blasting reduces dust and environmental contamination.

DIY sandblasting media options range from household baking soda to crushed glass and organic materials like walnut shells and corn cob grit. While some media like play sand are readily available, they pose serious health risks and should be avoided. Baking soda is a safe, gentle, and effective DIY media for delicate surfaces, while crushed glass offers a more aggressive, eco-friendly option. Always prioritize safety by using proper PPE, ensuring ventilation, and avoiding toxic or hazardous materials. Testing media on a small area and choosing the right abrasive for your surface will yield the best results.

Baking soda is considered the safest due to its non-toxic, biodegradable nature and gentle abrasive properties.

No. Play sand contains silica, which is hazardous to inhale and can cause silicosis.

Use wet blasting if possible, wear proper respirators, and blast in well-ventilated areas.

Yes, crushed glass is effective and eco-friendly but requires careful handling and protective gear.

Technically yes, by crushing shells, but it requires equipment and safety precautions; purchasing is recommended.

[1] https://www.lematec-tools.com/sandblasting-media-sandblast-reference

[2] https://www.finishingsystems.com/blog/4-necessary-precautions-for-keeping-sandblasting-safe/

[3] https://coatingsystems.com/diy-sandblasting/

[4] https://ramrent-all.com/2023/01/beginners-guide-to-sandblasting-for-your-diy-project/

[5] https://www.worksafe.qld.gov.au/safety-and-prevention/hazards/workplace-hazards/dangers-in-your-workplace/abrasive-blasting/abrasive-blasting-general-health-and-safety-issues

[6] https://www.youtube.com/watch?v=HmgzS_0QmB4

[7] https://istsurface.com/abrasive-media-for-sandblasting-a-comprehensive-guide/

[8] https://int-enviroguard.com/blog/abrasive-blasting-safety-tips-and-ppe/

[9] https://www.youtube.com/watch?v=N8SML-qgH9A

[10] https://www.instructables.com/Make-Your-Own-Sandblaster-and-How-To-Use-It/

[11] https://trinco.com/sandblasting-a-guide-to-safe-handling/

[12] https://www.lematec-tools.com/safety-glasses-sandblasting-application

[13] https://hamiltonblastandpaint.co.nz/news-updates/safety-tips-and-best-practices-for-abrasive-blasting/

[14] https://www.reddit.com/r/Sandblasting/comments/1b90u8n/there_must_be_a_way_to_make_your_own_blast_media/

[15] https://www.lematec-tools.com/application-correct-sand-media-guide-sandblasting

[16] https://www.youtube.com/watch?v=I5Q6FFyXGmU

[17] https://www.eastwood.com/garage/which-abrasive-blasting-media-is-correct-for-your-project/

[18] https://www.sharrettsplating.com/blog/7-tips-for-choosing-abrasive-blasting-media/

[19] https://www.youtube.com/watch?v=WwBrMZ8gxTc

[20] https://coatingsystems.com/diy-sandblasting/

[21] https://www.crystalsodablast.com/blog/sandblasting/diy-sandblasting-the-safe-way

[22] https://www.reddit.com/r/Sandblastingporn/comments/135tiza/complete_beginner_safety_questions_for_diyhobby/

[23] https://www.angi.com/articles/alternatives-to-sandblasting.htm

[24] https://www.instructables.com/Make-Your-Own-Sandblaster-and-How-To-Use-It/

[25] https://www.meremblasting.com/diy-sandblasting-at-home

[26] https://www.osha.gov/sites/default/files/publications/OSHA3697.pdf

[27] https://www.kramerindustriesonline.com/safety-practices-when-using-aluminum-oxide-media-in-sandblasting/

[28] https://istsurface.com/abrasive-media-for-sandblasting-a-comprehensive-guide/

[29] https://www.finishingsystems.com/blog/sandblasting-setup-and-applications/

[30] https://painters-london.ca/sandblasting-diy-guide/

[31] https://www.finishingsystems.com/blog/sandblasting-material-guide/

[32] https://www.youtube.com/watch?v=OLcdxK-TbXw

[33] https://www.reddit.com/r/woodworking/comments/mmqhd9/sandblasting_tips_for_beginner/

[34] https://www.instructables.com/DIY-500-Sandblaster/

[35] https://www.dustlessblasting.com/blog/a-guide-to-sand-blast-media

[36] https://www.youtube.com/watch?v=wqjusDoLlpA

[37] https://geekhack.org/index.php?topic=85846.0

[38] https://support.dustlessblasting.com/en/blasting-basics/what-media-should-i-use-

Top Pure Silicon Carbide Manufacturers and Suppliers in Russia

Top Pure Silicon Carbide Manufacturers and Suppliers in France

Top Pure Silicon Carbide Manufacturers and Suppliers in Arabia

Top Polishing Silicon Carbide Manufacturers and Suppliers in Thailand

Top Polishing Silicon Carbide Manufacturers and Suppliers in Turkey

Top Polishing Silicon Carbide Manufacturers and Suppliers in Vietnam

Top Polishing Silicon Carbide Manufacturers and Suppliers in South Korea

Top Polishing Silicon Carbide Manufacturers and Suppliers in Japan

Top Polishing Silicon Carbide Manufacturers and Suppliers in Poland

Top Polishing Silicon Carbide Manufacturers and Suppliers in Portugal