Views: 222 Author: Wendy Publish Time: 2025-11-27 Origin: Site

Content Menu

● Understanding White Silicon Carbide

● Key Properties and Advantages

● Main Applications in Vietnam

>> Abrasives and Surface Preparation

>> Refractories and High‑Temperature Equipment

>> Advanced Ceramics and Emerging Technologies

● Why Vietnam Is Becoming a White Silicon Carbide Hub

● Leading White Silicon Carbide Manufacturers and Suppliers in Vietnam

>> Local Silicon Carbide Producers

>> Abrasive and Refractory Distributors

>> Global Groups Serving Vietnam

● Role of Chinese Manufacturers in the Vietnam Supply Chain

>> Cooperation Models with Vietnamese Customers

● Technical Considerations When Sourcing White Silicon Carbide

>> Purity and Chemical Composition

>> Physical Properties and Testing

● Logistics and Packaging for Global Buyers

● Environmental and Sustainability Considerations

● How to Evaluate and Qualify a New Supplier

● FAQ

>> Q1: What makes White Silicon Carbide different from other silicon carbide types?

>> Q2: Which industries in Vietnam benefit most from White Silicon Carbide?

>> Q3: How can buyers ensure stable quality when sourcing from Vietnam?

>> Q4: What role do Chinese manufacturers play in the Vietnamese White Silicon Carbide market?

>> Q5: What should be considered when selecting White Silicon Carbide for a new product?

Vietnam is rapidly developing into an attractive destination for sourcing White Silicon Carbide because of its expanding abrasives, refractories, and high‑tech materials industries. For global buyers, combining the top White Silicon Carbide manufacturers and suppliers in Vietnam supply channels with experienced Chinese producers is an effective way to secure stable, high‑quality White Silicon Carbide at competitive cost.

![]()

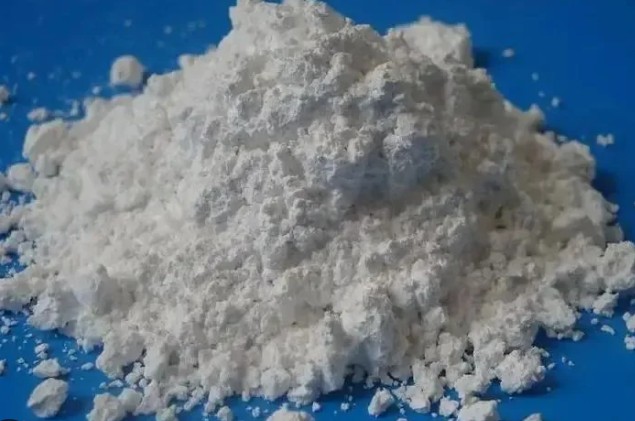

White Silicon Carbide is a high‑purity crystalline silicon carbide produced in electric resistance furnaces using carefully selected silica and carbon sources under strictly controlled conditions. Compared with conventional silicon carbide, White Silicon Carbide features lower impurity content, a sharper and more friable grain, and a lighter color, making it ideal for precision grinding and high‑grade refractory products.

In practice, White Silicon Carbide is supplied in a full spectrum of macro and micro grit sizes following FEPA, ANSI, or JIS standards. From coarse grains used in grinding wheels and refractory castables to ultra‑fine powders for lapping, polishing, and specialty ceramics, this flexibility allows manufacturers in Vietnam and abroad to fine‑tune performance for each application.

White Silicon Carbide combines extreme hardness with excellent thermal and chemical stability. This material ranks just below superabrasives such as diamond and cubic boron nitride, giving it aggressive cutting ability and long life in demanding grinding operations.

Its high thermal conductivity and resistance to thermal shock make White Silicon Carbide particularly suitable for furnace linings, kiln furniture, and other high‑temperature components. In many corrosive or oxidizing atmospheres, White Silicon Carbide outperforms conventional refractories by resisting slag attack and chemical degradation, thereby extending service life and reducing downtime.

Vietnam's abrasives industry uses large volumes of White Silicon Carbide for both bonded and coated products. Grinding wheel manufacturers rely on White Silicon Carbide grains to produce wheels that cut stainless steel, tool steel, and hard non‑ferrous materials with reduced burning and improved dimensional accuracy. Coated abrasives converters use White Silicon Carbide in belts, discs, and papers for glass, stone, composites, and hard alloys where fast cutting and clean surfaces are required.

In surface preparation and blasting processes, carefully selected White Silicon Carbide grains provide consistent profiles on metal or stone while maintaining recyclability and minimizing contamination. This is especially important for industries that prepare surfaces for thermal spraying, painting, or bonding, where surface cleanliness directly impacts coating performance.

Refractory producers in and around Vietnam integrate White Silicon Carbide into castables, gunning mixes, plastic refractories, and pre‑cast shapes for critical furnace and ladle areas. White Silicon Carbide improves resistance to abrasion, slag penetration, and thermal cycling, making it a preferred ingredient for steel, foundry, non‑ferrous, and heat‑treatment applications.

Kiln furniture and thermal ceramic components made with White Silicon Carbide can withstand rapid temperature changes and high heat loads while maintaining mechanical strength. This performance is important for ceramic kilns, powder metallurgy furnaces, and other high‑temperature equipment common in Vietnam's growing manufacturing sector.

Beyond traditional abrasives and refractories, White Silicon Carbide also supports more advanced ceramic and engineering applications. Its combination of hardness, thermal conductivity, and corrosion resistance suits pump components, mechanical seals, wear‑resistant nozzles, and special structural ceramics.

As Vietnam strengthens its position in electronics and semiconductors, silicon carbide in general is gaining strategic importance. While wafer‑grade silicon carbide requires specialized processes beyond standard abrasives production, the technical expertise and supply chains built around White Silicon Carbide will support this longer‑term development.

Vietnam offers several structural advantages that support the growth of White Silicon Carbide production and distribution. The country benefits from access to suitable mineral resources, competitive labor and energy costs, and proximity to major shipping routes serving Asia, Europe, and the Americas.

Government policies in Vietnam emphasize industrial upgrading, high‑tech materials, and export‑oriented manufacturing. This creates favorable conditions for abrasives, refractories, and advanced ceramics companies that depend on reliable White Silicon Carbide supply. At the same time, foreign direct investment in manufacturing pushes local suppliers to improve quality control, documentation, and environmental performance.

Vietnam hosts silicon carbide producers that operate electric resistance furnaces and downstream processing lines for crushing, sizing, and classifying grains. These producers typically offer a range of black and green silicon carbide grades and, in some cases, higher‑purity products that can be refined or selected for White Silicon Carbide applications.

By working directly with local producers, buyers can benefit from shorter lead times, regionally competitive pricing, and the ability to coordinate shipments with other industrial materials sourced from Vietnam. Close cooperation on raw material selection, furnace parameters, and post‑processing helps align product characteristics with the requirements of high‑end abrasives and refractories.

A network of Vietnamese distributors and trading companies specializes in abrasives, refractory raw materials, and industrial minerals. These firms often stock silicon carbide grains and powders, including White Silicon Carbide, together with complementary materials such as fused alumina, bauxite, calcined alumina, and refractory clays.

For many small and medium‑sized users, purchasing White Silicon Carbide through these distributors is more practical than importing full container loads directly from overseas producers. Distributors can break bulk, offer mixed‑cargo shipments, and provide local technical support, all of which reduce inventory risk and improve responsiveness to market fluctuations.

International abrasives and advanced materials groups supply White Silicon Carbide into Vietnam through regional warehouses, agents, and subsidiaries. These companies bring established brand recognition, mature quality systems, and the capability to deliver specialized grades for critical applications.

For global tool manufacturers and multinational end users operating in Vietnam, sourcing White Silicon Carbide from familiar global brands while leveraging local distribution can simplify qualification and ensure consistent performance across plants in different regions. This hybrid approach—combining global standards with local logistics—supports both quality assurance and cost optimization.

As a professional Chinese producer and exporter of high‑quality abrasives and refractory materials, a company can play a key role in supporting Vietnam's White Silicon Carbide demand. Chinese producers typically operate large‑scale furnaces, advanced purification and sizing lines, and comprehensive laboratory facilities, enabling them to deliver a wide range of White Silicon Carbide products with stable quality.

There are several effective cooperation models between Chinese manufacturers and Vietnamese customers:

- OEM and private‑label supply for grinding wheel factories, coated abrasives converters, and refractory plants in Vietnam that want stable quality White Silicon Carbide under their own brands.

- Joint product development to tailor White Silicon Carbide grain shape, toughness, and particle size distribution to specific bonding systems, presses, kilns, or casting practices used by Vietnamese manufacturers.

- Regional stock and just‑in‑time delivery, where Chinese producers coordinate with local warehouses or distributors in Vietnam to keep critical White Silicon Carbide grades available for fast shipment, minimizing customer inventory.

By integrating technical service, logistics planning, and commercial flexibility, Chinese manufacturers help their Vietnamese partners upgrade product performance, reduce costs, and compete more effectively in both domestic and export markets.

For high‑performance abrasives and refractories, purity is one of the most critical parameters when evaluating White Silicon Carbide. Buyers should pay special attention to:

- Minimum SiC content and maximum levels of free silica, iron oxide, and other metallic impurities.

- Control of trace elements that may affect corrosion resistance, oxidation behavior, or electrical characteristics in specialized applications.

Consistent chemistry helps ensure predictable grinding behavior, refractory corrosion resistance, and thermal shock performance. Suppliers who operate reliable raw material sourcing and in‑house laboratories are better positioned to maintain this consistency over time.

White Silicon Carbide performance is strongly influenced by grain size distribution and particle shape. Narrow particle size distributions support more precise surface finishes and uniform packing in grinding wheels or refractory mixes.

Grain shape affects aggressiveness and wear: sharper, more blocky White Silicon Carbide grains can deliver faster cutting, while slightly more rounded grains may improve wheel life or reduce brittleness in certain refractories. When working with new Vietnamese suppliers, customers should review detailed sieve analysis data and, where possible, carry out microscopic evaluation or trial blending.

Important physical properties for White Silicon Carbide include bulk density, true density, and, in some cases, specific surface area. These factors influence how the grains pack in a bond or matrix and how the material behaves during firing or curing.

Comprehensive quality control should include routine testing of particle size distribution, magnetic content, moisture, and, for micro powders, flowability and specific surface area. Customers who share their process conditions and performance targets with suppliers will normally receive better‑matched White Silicon Carbide specifications.

For overseas buyers sourcing from Vietnamese White Silicon Carbide manufacturers and suppliers, packaging and logistics planning are essential parts of a successful supply strategy. Typical packaging options include:

- Jumbo bags for bulk White Silicon Carbide shipments to large grinding wheel or refractory plants.

- Smaller 25 kg or 40 kg bags stacked on pallets for easier handling and warehouse management.

- Customized packaging with moisture protection or color‑coded labels to distinguish different grit sizes and grades.

Efficient container loading, clear pallet labeling, and accurate documentation help avoid delays and damage in transit. When customers work simultaneously with Vietnamese and Chinese suppliers, aligning packaging standards and labeling systems simplifies internal logistics and inventory control.

Modern abrasives and refractory customers increasingly focus on environmental and sustainability performance throughout their supply chains. Leading White Silicon Carbide producers in China and Vietnam are investing in cleaner furnace technologies, waste heat recovery, dust collection, and improved emissions control.

For buyers, engaging with suppliers that document their environmental measures and energy efficiency can support corporate sustainability reporting and long‑term risk management. Furthermore, stable, high‑quality White Silicon Carbide that extends tool life or refractory lining life contributes indirectly to lower resource consumption and waste generation at end‑user facilities.

When evaluating a new White Silicon Carbide supplier in Vietnam, a structured qualification process can reduce risk and speed up adoption:

1. Initial technical review: Collect detailed specifications, chemical analysis, and typical test certificates for proposed White Silicon Carbide grades.

2. Sample testing: Run laboratory tests and small‑scale production trials in grinding wheels, coated abrasives, or refractory products to compare performance with existing materials.

3. Plant audit or virtual tour: Assess furnace operations, raw material handling, screening and classification equipment, laboratory capabilities, and quality systems.

4. Pilot orders: Place limited commercial orders to validate stability of White Silicon Carbide supply, packaging quality, and logistics reliability.

5. Long‑term agreement: Once performance and reliability are confirmed, negotiate long‑term cooperation, including price mechanisms, safety stock arrangements, and continuous improvement programs.

This step‑by‑step approach can be applied both to Vietnamese producers and to Chinese manufacturers who supply White Silicon Carbide into the Vietnamese market or directly to global customers.

Vietnam is steadily strengthening its position as a key sourcing base for White Silicon Carbide, supported by local silicon carbide producers, a growing network of abrasives and refractory distributors, and a dynamic manufacturing environment. For international buyers, the combination of Vietnamese supply channels and experienced Chinese manufacturers offers an attractive balance of quality, cost, and flexibility.

By focusing on purity, grain size control, and consistent physical properties, manufacturers in abrasives, refractories, advanced ceramics, and high‑temperature equipment can fully leverage the advantages of White Silicon Carbide. Careful supplier qualification, close technical cooperation, and well‑planned logistics will allow companies to secure reliable White Silicon Carbide supply as demand continues to expand in Vietnam and worldwide.

![]()

White Silicon Carbide is characterized by higher purity and a lighter color, typically produced using selected raw materials and controlled furnace conditions. This results in sharper, more friable grains that provide fast cutting and fine finishes in precision grinding and high‑grade refractories.

The main industries are bonded and coated abrasives manufacturing, refractory production for steel and foundry applications, and thermal ceramics such as kiln furniture and furnace components. As Vietnam's electronics and advanced materials sectors grow, more specialized uses of White Silicon Carbide are also emerging.

Buyers should request detailed technical specifications, regular test certificates, and clear quality documentation for each White Silicon Carbide shipment. Conducting internal trials, performing periodic audits, and maintaining open technical communication with suppliers help keep quality consistent over the long term.

Chinese manufacturers provide large‑scale furnace capacity, advanced processing lines, and extensive experience in producing White Silicon Carbide for global markets. By partnering with Vietnamese distributors and end users, they supply customized grades, joint product development, and stable long‑term supply into Vietnam and other regions.

Key factors include required purity, target grit size range, grain shape and toughness, bulk density, and compatibility with the intended bond or matrix system. It is best to work closely with White Silicon Carbide suppliers, share process details, and run controlled trials to identify the optimal grade for each application.

[1](https://digitalcommons.mtech.edu/cgi/viewcontent.cgi?article=1270&context=grad_rsch)

[2](https://nhqsic.com)

[3](https://www.ipsceramics.com/tag/silicon-carbide/)

[4](https://patents.google.com/patent/ES2649637T3/en)

[5](https://www.iwatani.co.jp/eng/business/material/resources-advanced/products/si/)

[6](https://www.onsemi.com/solutions/technology/silicon-carbide-sic)

[7](https://www.coherent.com/news/press-releases/coherent-expands-silicon-carbide-epitaxial-wafer-production)

Top Pure Silicon Carbide Manufacturers and Suppliers in Russia

Top Pure Silicon Carbide Manufacturers and Suppliers in France

Top Pure Silicon Carbide Manufacturers and Suppliers in Arabia

Top Polishing Silicon Carbide Manufacturers and Suppliers in Thailand

Top Polishing Silicon Carbide Manufacturers and Suppliers in Turkey

Top Polishing Silicon Carbide Manufacturers and Suppliers in Vietnam

Top Polishing Silicon Carbide Manufacturers and Suppliers in South Korea

Top Polishing Silicon Carbide Manufacturers and Suppliers in Japan

Top Polishing Silicon Carbide Manufacturers and Suppliers in Poland

Top Polishing Silicon Carbide Manufacturers and Suppliers in Portugal