Views: 222 Author: Wendy Publish Time: 2025-12-05 Origin: Site

Content Menu

● Understanding Silicon Carbide Sanding

● Why Silicon Carbide Sanding Is Popular in Portugal

● Main Types of Silicon Carbide Sanding Products

● Key Players in Portugal's Silicon Carbide Sanding Ecosystem

● Applications of Silicon Carbide Sanding in Portuguese Industry

● Technical Advantages of Silicon Carbide Sanding

● How Overseas OEM Producers Support the Portuguese Market

● Purchasing Tips for Silicon Carbide Sanding in Portugal

● Recommended Content Sections, Images, and Videos

● Opportunities for Global Buyers Targeting Portugal

● FAQ – Silicon Carbide Sanding in Portugal

>> 1. What is Silicon Carbide Sanding used for in Portugal?

>> 2. Why choose Silicon Carbide Sanding instead of aluminum oxide?

>> 3. How can I select the right Silicon Carbide Sanding product?

>> 4.Can Portuguese companies work with Chinese OEM factories for Silicon Carbide Sanding?

>> 5. What quality checks are important for Silicon Carbide Sanding?

Portugal has become an important gateway for high‑performance Silicon Carbide Sanding products into the European market, serving automotive repair, metalworking, wood and furniture, stone processing, and construction sectors. Portuguese abrasive converters, trading houses, and distributors work closely with global brands to bring advanced Silicon Carbide Sanding papers, belts, and discs to top Silicon Carbide Sanding manufacturers and suppliers in Germany.

![]()

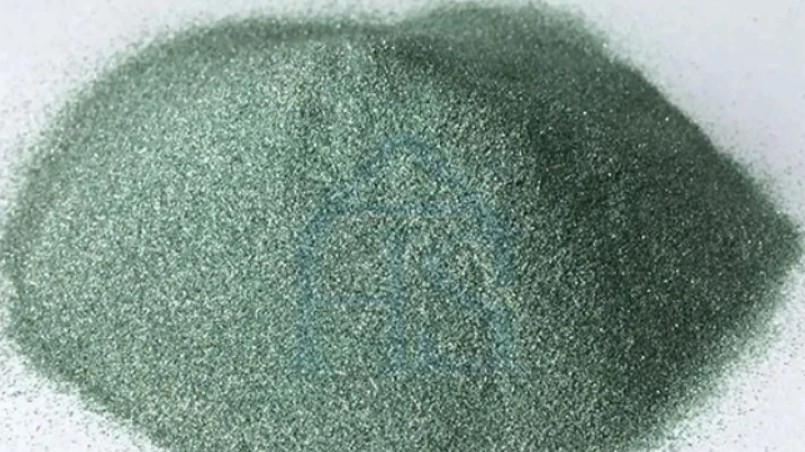

Silicon Carbide Sanding refers to sanding papers, belts, discs, and specialty products that use silicon carbide (SiC) grain as the cutting abrasive. Silicon carbide is extremely hard, typically rated around 9–9.5 on the Mohs scale, which gives Silicon Carbide Sanding products aggressive cutting power on very hard or brittle materials.

Compared with conventional aluminum oxide abrasives, Silicon Carbide Sanding is sharper and cuts faster but tends to wear slightly quicker, making it ideal for fine finishing, wet sanding, and precision grinding of glass, ceramics, stone, non‑ferrous metals, and composites. This balance between fast cutting and fine finishing explains why Silicon Carbide Sanding is highly valued wherever high‑quality surfaces are required.

Portuguese industry serves diverse sectors such as automotive refinishing, construction, shipbuilding, decorative stone, and furniture, all of which rely heavily on Silicon Carbide Sanding for high‑quality surfaces. The country's position within the EU means that local users follow strict quality, safety, and environmental standards, encouraging adoption of premium Silicon Carbide Sanding materials.

Local workshops and factories increasingly favor waterproof Silicon Carbide Sanding papers and high‑efficiency flap discs that help reduce labor time and rework. This trend supports a strong demand for consistent, high‑performance Silicon Carbide Sanding products and opens the door for international OEM suppliers to cooperate with Portuguese partners.

The Portuguese market uses a wide range of Silicon Carbide Sanding formats tailored to different applications and machinery. Typical product categories include:

- Waterproof sheets – Silicon Carbide Sanding sheets designed for wet or dry sanding of automotive paints, primers, clear coats, and metals.

- Belts – Narrow and wide Silicon Carbide Sanding belts for metal fabrication, glass edging, stone calibration, and composite panel lines.

- Discs and fiber discs – Silicon Carbide Sanding discs for orbital sanders and angle grinders, used in maintenance, repair, and production environments.

- Foils and films – Thin‑backed Silicon Carbide Sanding foils and films offering highly consistent finishes for laboratory work, electronics, and precision engineering.

- Specialty products – Non‑woven pads, flap wheels, and combination tools that integrate Silicon Carbide Sanding grains for specific finishing tasks.

Each type of Silicon Carbide Sanding product focuses on a particular combination of cutting speed, surface finishing ability, flexibility, and durability, allowing Portuguese users to match abrasives precisely to each job.

Portugal's Silicon Carbide Sanding landscape is formed by a mix of local manufacturers, converters, distributors, and international brands. Local producers manufacture coated abrasives and complementary rigid tools, while foreign brands supply high‑tech Silicon Carbide Sanding materials that are stocked and marketed by Portuguese partners.

Examples of roles within this ecosystem include:

- Local abrasive manufacturers in Portugal that produce coated abrasives, flap wheels, resin‑bonded wheels, and sanding accessories. Many of these companies either use silicon carbide grain directly or offer Silicon Carbide Sanding products within wider ranges.

- National distributors and technical organizations that build networks of industrial clients and retailers, providing stock, logistics, and application support for Silicon Carbide Sanding products.

- International coated abrasive brands from Europe and beyond that manufacture silicon carbide papers, belts, and discs, then supply them into Portugal through dealers, subsidiaries, or importers.

- Large industrial supply houses and hardware chains that carry waterproof Silicon Carbide Sanding sheets and discs for workshops, garages, and small enterprises.

The interaction between these groups ensures good availability of Silicon Carbide Sanding solutions across different price and performance levels, from premium European products to cost‑effective OEM lines.

Silicon Carbide Sanding is used everywhere that clean, accurate surfaces are needed before painting, coating, bonding, or assembly. In Portugal, several application clusters stand out:

- Automotive and transportation – Car body shops and repair centers use waterproof Silicon Carbide Sanding sheets to level fillers, primers, and clear coats. Silicon Carbide Sanding discs are also used to prepare panels for repainting and to blend repair areas.

- Metal fabrication and maintenance – Fabricators and maintenance teams rely on Silicon Carbide Sanding belts and discs to remove rust, scale, and weld discoloration, especially on stainless steel, aluminum, and non‑ferrous alloys where aggressive yet controlled cutting is essential.

- Stone and tile processing – Portugal's decorative stone and tile sector applies Silicon Carbide Sanding belts and foils for calibrating, smoothing, and polishing granite, marble, engineered stone, and ceramic surfaces.

- Woodworking and furniture – Although aluminum oxide abrasives are common for wood, Silicon Carbide Sanding can be used for intermediate finishing, lacquer sanding, and special coatings where a very fine finish is required.

- Electronics and precision engineering – Silicon Carbide Sanding films and fine‑grit papers are employed to achieve precise surface roughness on metals and components used in electronics and high‑precision assemblies.

Because Silicon Carbide Sanding is available in a full grit range from coarse to micro‑fine, Portuguese users can design complete sanding systems from rough stock removal down to final polishing.

From a technical viewpoint, Silicon Carbide Sanding offers several advantages that make it particularly attractive to demanding users:

- High cutting efficiency – The sharp, angular shape of silicon carbide grains gives Silicon Carbide Sanding a fast initial cut, which is ideal for quickly removing coatings, oxides, and material layers.

- Excellent performance on hard and brittle materials – Silicon Carbide Sanding is much more effective than many alternatives on glass, ceramics, stone, carbides, and hard alloys because the grain can penetrate and fracture these materials cleanly.

- Good performance in wet sanding – Silicon Carbide Sanding is often paired with waterproof paper or cloth backings, allowing use with water or coolants that flush debris away, reduce heat, and deliver superior finishes.

- Fine finishing capability – Silicon Carbide Sanding can be produced in extremely fine grits, delivering low surface roughness and a smooth, even appearance on coatings and metals.

These technical strengths explain why Silicon Carbide Sanding plays such a central role in high‑end industrial finishing across Portugal.

Although Portugal has its own abrasive industry, a significant portion of Silicon Carbide Sanding products is imported. Overseas OEM manufacturers, especially in China, offer strong support to Portuguese distributors, converters, and brand‑owners.

A specialized Chinese factory focusing on Silicon Carbide Sanding can typically provide:

- Customized specifications – Tailor‑made Silicon Carbide Sanding waterproof papers, belts, and discs matched to Portuguese dimensions, hole patterns, and grit sequences.

- Private‑label services – Complete branding solutions, including printed backings, labels, and packaging, helping Portuguese partners build their own Silicon Carbide Sanding brands.

- Cost‑competitive production – Efficient manufacturing of Silicon Carbide Sanding products using large‑scale coating, curing, and conversion lines to keep unit costs low.

- Quality and testing support – Laboratory testing of silicon carbide grain size distribution, adhesion, backing strength, and performance to ensure each batch of Silicon Carbide Sanding meets consistent standards.

- Logistics and stocking flexibility – Container‑load shipments and scheduled deliveries that allow Portuguese distributors to plan inventory and reduce local manufacturing investments.

By integrating Chinese OEM supply with local Portuguese sales and technical support, distributors can broaden their Silicon Carbide Sanding portfolio and respond quickly to market changes.

For industrial buyers and distributors, choosing the right Silicon Carbide Sanding supplier involves both technical and business considerations. Key tips include:

- Define the application clearly – Specify whether the Silicon Carbide Sanding product will be used on metal, stone, glass, composites, or coatings, and identify whether the process is dry or wet.

- Specify grit ranges and backing types – Decide the full grit sequence required (for example, P80–P2000) and choose between paper, cloth, film, or combination backings for your Silicon Carbide Sanding needs.

- Request data sheets and samples – Ask suppliers to provide cutting‑rate data, lifetime tests, and surface roughness results, then verify performance through trial runs with representative Silicon Carbide Sanding products.

- Check consistency and batch control – Ensure that the supplier has quality systems to keep Silicon Carbide Sanding properties stable from batch to batch, including resin bonds, grain coating weights, and anti‑clogging treatments.

- Evaluate service and technical support – Give preference to partners who can recommend the right Silicon Carbide Sanding specification, solve application issues, and supply training or demonstrations.

- Compare total cost, not only price – A slightly more expensive Silicon Carbide Sanding product may reduce labor, scrap, and tool change time, resulting in lower total cost per finished part.

These steps help Portuguese buyers and international customers build long‑term relationships with reliable Silicon Carbide Sanding manufacturers and suppliers.

![]()

To maximize engagement and SEO performance, a blog article about Silicon Carbide Sanding in Portugal should integrate visuals and multimedia throughout the text. While the actual links are added in your CMS, you can plan sections like:

- Silicon Carbide Sanding Product Gallery – Photos of sheets, belts, discs, and films in various grits and backing types.

- Silicon Carbide Sanding in Portuguese Workshops – Short clips showing technicians sanding car panels, metal fabrications, or stone tiles using Silicon Carbide Sanding tools.

- OEM Manufacturing of Silicon Carbide Sanding – Factory‑floor images from mixing and coating silicon carbide grains to jumbo rolls and final converted products.

- Quality Inspection for Silicon Carbide Sanding – Visuals of lab instruments, roughness measurements, and comparison between surfaces finished with different grits.

Each visual block can include concise captions that naturally repeat the keyword “Silicon Carbide Sanding” while explaining the scene, giving both search engines and human readers a clear understanding of your expertise.

For global trading companies, distributors, or end‑users targeting the Portuguese market, Silicon Carbide Sanding offers multiple opportunities:

- Niche product development – Specialty Silicon Carbide Sanding products such as extra‑wide belts for stone lines, ultra‑fine films for electronics, or low‑VOC coated papers tailored to EU regulations.

- Hybrid sourcing strategies – Combining premium European Silicon Carbide Sanding products for demanding applications with cost‑effective OEM solutions from China for general‑purpose use.

- Brand building – Launching private‑label Silicon Carbide Sanding brands that address specific Portuguese market segments (body shops, metal workshops, stone fabricators).

- Technical collaboration – Working with both Portuguese and overseas engineers to optimize process parameters, reduce sanding steps, and improve finished quality using better Silicon Carbide Sanding systems.

These strategies allow buyers not only to sell Silicon Carbide Sanding products in Portugal, but also to create sustainable, value‑added partnerships throughout the supply chain.

Portugal's abrasives sector offers a dynamic and mature environment for Silicon Carbide Sanding, supported by local manufacturers, converters, and distributors who understand the needs of automotive, metalworking, stone, woodworking, and precision industries. At the same time, international coated abrasive brands and competitive OEM producers enrich the market with a broad portfolio of Silicon Carbide Sanding sheets, belts, discs, and films.

By combining the strengths of Portuguese distribution networks with reliable overseas OEM production, buyers can secure high‑quality, cost‑effective Silicon Carbide Sanding products tailored to almost any application. Clear technical communication, rigorous testing, and long‑term partnerships are the keys to unlocking the full potential of Silicon Carbide Sanding in Portugal's industrial landscape.

In Portugal, Silicon Carbide Sanding is widely used for automotive refinishing, metal fabrication, stone and tile processing, woodworking, and precision engineering. It helps prepare surfaces before painting or coating, removes defects, and achieves fine finishes on metals, glass, ceramics, and composites.

Silicon Carbide Sanding uses sharper, harder grains than aluminum oxide, giving faster cutting and better performance on hard or brittle materials like glass, ceramics, and stone. It also performs very well in wet sanding, delivering smooth surfaces and reduced clogging compared with many standard abrasives.

Start by defining your material, process (dry or wet), and desired finish, then choose an appropriate backing (paper, cloth, or film) and grit sequence for your Silicon Carbide Sanding system. Request technical data sheets and samples from suppliers, and run line trials to confirm cutting rate, lifetime, and surface quality.

Yes. Many Portuguese distributors and industrial users cooperate with Chinese OEM manufacturers to source customized Silicon Carbide Sanding sheets, belts, and discs. These partnerships provide cost‑effective products, private‑label options, and flexible packaging while still meeting European quality and regulatory requirements.

Key checks include grain size distribution, coating weight, adhesion strength between grain and backing, resistance to tearing or stretching, and performance tests for cutting rate and lifetime. Reliable Silicon Carbide Sanding suppliers provide test reports and maintain strict batch‑to‑batch consistency so users can depend on stable results.

Top Pure Silicon Carbide Manufacturers and Suppliers in Russia

Top Pure Silicon Carbide Manufacturers and Suppliers in France

Top Pure Silicon Carbide Manufacturers and Suppliers in Arabia

Top Polishing Silicon Carbide Manufacturers and Suppliers in Thailand

Top Polishing Silicon Carbide Manufacturers and Suppliers in Turkey

Top Polishing Silicon Carbide Manufacturers and Suppliers in Vietnam

Top Polishing Silicon Carbide Manufacturers and Suppliers in South Korea

Top Polishing Silicon Carbide Manufacturers and Suppliers in Japan

Top Polishing Silicon Carbide Manufacturers and Suppliers in Poland

Top Polishing Silicon Carbide Manufacturers and Suppliers in Portugal