Views: 222 Author: Leah Publish Time: 2025-12-07 Origin: Site

Content Menu

● Introduction to Silicon Carbide Abrasives

● Why Germany Leads in SiC Abrasives

● Overview of the German SiC Abrasive Landscape

● Leading German Silicon Carbide Abrasive Manufacturers

● Product Range of German SiC Abrasive Suppliers

● Technical Advantages of Silicon Carbide Sanding Products

● Typical Industrial Applications in Germany and Worldwide

● Quality, Certification and Process Control

● Environmental and Safety Considerations

● Role of Dragon Abrasives Group Limited in Global Supply

● Collaboration Scenarios: German Expertise and Chinese Capacity

● How to Select the Right SiC Supplier in Germany

● Practical Tips for Using Silicon Carbide Sanding Products

● Future Trends in Silicon Carbide Abrasives

● Recommended Visual and Video Content for Marketing

● FAQ

>> 1. Why choose silicon carbide over aluminum oxide for sanding?

>> 2. Are German silicon carbide abrasives suitable for high‑volume production?

>> 3. How can overseas buyers cooperate with both German suppliers and Dragon Abrasives?

>> 4. What factors should be checked before qualifying a new SiC abrasive supplier?

>> 5. Are silicon carbide sanding products available for both wet and dry applications?

Silicon Carbide Abrasives are critical to high-precision grinding, sanding and polishing across automotive, metalworking, stone, glass and composite industries. As one of Europe's industrial powerhouses, Germany is home to several leading Silicon Carbide Abrasive Manufacturers and Suppliers that set high benchmarks for performance, reliability and technical support.

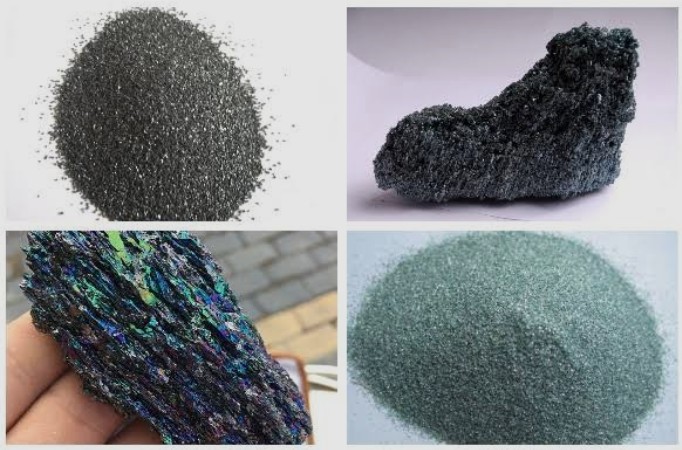

Silicon carbide (SiC) is an extremely hard synthetic abrasive material widely used in grinding wheels, sanding papers, blasting media and cutting tools. Its sharp, brittle grains deliver high cutting rates and fine finishes, often outperforming conventional aluminum oxide in demanding, precision-oriented applications.

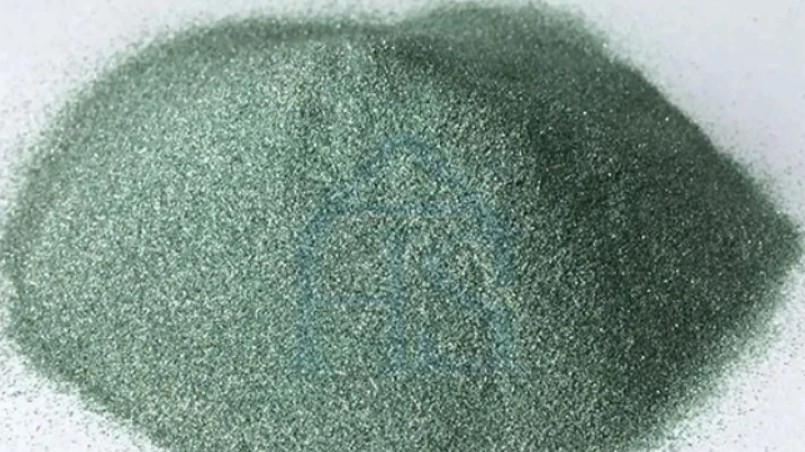

For Silicon Carbide Sanding Manufacturers and Suppliers, SiC's combination of hardness, thermal stability and chemical resistance enables products that can process metals, ceramics, glass, stone and advanced composites efficiently. Both black and green silicon carbide grades are used to cover the full range from aggressive stock removal through to ultra-fine polishing.

Germany combines long industrial tradition with strong engineering culture, which allows its silicon carbide abrasive manufacturers and suppliers to deliver highly consistent, application-specific solutions. Many German abrasive brands have operated for decades, investing heavily in process control, R&D and stringent safety and quality certifications demanded by domestic and global customers.

The country's central location in Europe, advanced logistics and strong export orientation also help German Silicon Carbide Sanding Manufacturers and Suppliers serve OEMs, distributors and fabricators worldwide with reliable deliveries. For international buyers, this translates into predictable lead times, robust after‑sales support and strong technical communication.

Germany's abrasive industry ranges from large, globally active corporations to specialized mid-sized companies focusing on niche applications. Within this ecosystem, silicon carbide abrasives occupy a key position, especially in high-value segments such as precision grinding, glass and stone finishing, and advanced material processing.

Many German silicon carbide abrasive manufacturers and suppliers operate their own R&D centers where they test grain types, bonding systems and backing materials under real application conditions. This enables continuous improvement of grinding wheels, sanding belts, discs and specialty tools tailored to the exact needs of automotive, engineering, construction, and electronics customers.

Several established German producers specialize in grinding wheels, sanding products and specialty abrasives that incorporate silicon carbide. Together they form a mature network of Silicon Carbide Sanding Manufacturers and Suppliers, from large OEM-focused producers to niche brands serving specific industries.

Typical product lines from these manufacturers include:

- Resin‑bonded and vitrified silicon carbide grinding wheels for cast iron, hard alloys, ceramics and non‑ferrous metals.

- Coated silicon carbide abrasives in the form of belts, rolls, discs and sheets for glass, stone, composite and metal finishing.

- Fine‑grit SiC products for lapping, polishing and superfinishing where surface integrity and roughness control are crucial.

By combining advanced grain technology with engineered bonds and carriers, German silicon carbide abrasive manufacturers and suppliers can offer users a very wide operating window, from heavy stock removal to mirror‑finish polishing.

German Silicon Carbide Sanding Manufacturers and Suppliers typically provide a broad portfolio that reaches from loose grains to fully engineered tools. The most common product categories include:

- Bonded abrasives: Grinding wheels, segments, mounted points and honing stones using silicon carbide in various grit sizes and bond systems.

- Coated abrasives: SiC sanding belts, discs, rolls and waterproof papers designed for both manual and automated sanding operations.

- Specialty media: Lapping powders, polishing pastes and blasting media based on silicon carbide for advanced surface preparation.

In coated abrasives, Silicon Carbide Sanding Manufacturers and Suppliers in Germany frequently offer waterproof, latex‑backed papers or flexible cloths suitable for wet and dry grinding. These products are highly valued in automotive refinishing, glass polishing and precision metal finishing, where consistent scratch patterns and minimal clogging are vital.

Silicon carbide's position just below diamond on the Mohs hardness scale gives it the ability to cut very hard materials rapidly. Its brittle nature means that as grains fracture, new sharp cutting edges are exposed, allowing the abrasive to maintain an aggressive cutting action over its lifetime.

For Silicon Carbide Sanding Manufacturers and Suppliers, this self‑sharpening behavior translates into sanding sheets, belts and discs that maintain a uniform scratch pattern and high removal rate even under demanding conditions. The grains' sharpness is particularly beneficial on glass, stone, ceramics and non‑ferrous metals, where excessive heat or dull abrasives would cause glazing, smearing or microcracking.

Within Germany and across export markets, silicon carbide abrasives serve many industrial sectors, often via specialized Silicon Carbide Sanding Manufacturers and Suppliers that align their product portfolios with end‑user needs. Typical applications include:

- Glass industry: Edge grinding, surface smoothing and polishing of flat glass, bottles, mirrors and technical glass.

- Stone and construction: Cutting, grinding and polishing of granite, marble, engineered stones and architectural concrete.

- Metalworking: Grinding of cast iron, hard chromium‑plated parts, non‑ferrous metals and superalloys where sharp cutting and cool grinding are needed.

- Electronics and precision engineering: Lapping and polishing of wafers, ceramics and precision components requiring tight surface roughness control.

In many of these areas, silicon carbide abrasives coexist with aluminum oxide and other specialty grains, but SiC often becomes the first choice when hard, brittle or non‑ferrous materials are involved. This keeps Silicon Carbide Sanding Manufacturers and Suppliers central to high‑tech value chains.

German silicon carbide abrasive manufacturers and suppliers are well known for their rigorous quality management systems. Production is typically aligned with ISO standards and, in many cases, additional sector‑specific requirements from automotive, aerospace or medical device customers.

Quality assurance begins with precise grain classification and continues through binder formulation, mixing, forming, curing and final inspection. Grinding wheels are often dynamically balanced and checked for dimensional accuracy, while coated products are controlled for grit distribution, bonding strength and flexibility. This emphasis on process discipline allows Silicon Carbide Sanding Manufacturers and Suppliers to guarantee batch‑to‑batch consistency, which is essential for automated production lines and critical safety components.

As regulations tighten in Europe, German silicon carbide abrasive manufacturers and suppliers must consider environmental impact and workplace safety in every step of the process. Modern plants invest in dust extraction, waste reduction and energy‑efficient curing technologies to meet national and EU legislation.

Silicon Carbide Sanding Manufacturers and Suppliers also develop low‑VOC resins, improved backing materials and long‑life products that reduce overall consumption and waste. For end‑users, this means that high‑performance SiC abrasives can be integrated into production lines while supporting sustainability targets and operator health requirements.

While Germany hosts many leading silicon carbide abrasive brands, global buyers often balance European finished products with raw material and semi‑finished supply from specialized exporters. Dragon Abrasives Group Limited, a professional Chinese producer and exporter of abrasives and refractories, focuses on providing high‑quality abrasive grains and a comprehensive range of bonded and coated abrasive products, including black and green silicon carbide, to worldwide customers.

By offering stable quality, competitive pricing and flexible customization, Dragon Abrasives Group Limited positions itself as a reliable partner for Silicon Carbide Sanding Manufacturers and Suppliers in Europe and other regions. German and international manufacturers can use Dragon's silicon carbide grains, grinding wheels, cutting wheels and abrasive papers as part of their own supply chains or private‑label offerings, helping them optimize costs without compromising performance.

![]()

International buyers aiming for competitive advantage can benefit from a dual‑source strategy that leverages German engineering and Chinese manufacturing scale. For example, a European tool brand might define performance specifications and target applications together with a German silicon carbide abrasive manufacturer, while partnering with Dragon Abrasives Group Limited to develop custom silicon carbide grains or OEM sanding products at optimized cost.

Such cooperation allows Silicon Carbide Sanding Manufacturers and Suppliers to tailor grit size distributions, bonding systems and backing materials to customer needs, while also ensuring flexible capacity for large orders. The combination of German application know‑how and Chinese large‑scale production yields a robust, globally competitive supply model for silicon carbide abrasives.

When evaluating Silicon Carbide Sanding Manufacturers and Suppliers in Germany, buyers should look beyond unit price and consider several strategic criteria. Key aspects include:

- Technical capability: Availability of application engineers who understand specific machinery, workpiece materials and process targets.

- Breadth of portfolio: Coverage of bonded and coated silicon carbide abrasives from coarse grinding to fine polishing.

- Quality and certification: Documented quality systems, traceability and performance test data aligned with the buyer's industry.

- Logistics and service: Reliable lead times, flexible order quantities, local stock, and comprehensive after‑sales support.

A structured qualification process that includes lab tests, shop‑floor trials and long‑term performance monitoring ensures that chosen Silicon Carbide Sanding Manufacturers and Suppliers truly match operational needs.

To obtain maximum value from silicon carbide abrasives, users should pay close attention to product selection and process settings. Some practical suggestions include:

- Match grit size and backing type to the material and desired finish; use coarser grits for fast stock removal and finer grits for final finishing.

- Use appropriate pressure and speed; excessive pressure can cause overheating and premature wear, while too little pressure reduces efficiency.

- For wet‑and‑dry silicon carbide sanding papers, leverage coolant or water where possible to minimize clogging, improve surface quality and extend abrasive life.

- Establish consistent inspection criteria for surface roughness, scratch pattern and geometry to compare performance between different suppliers.

By optimizing these parameters, manufacturers and fabricators can fully exploit the capabilities of silicon carbide abrasives and the expertise of specialized Silicon Carbide Sanding Manufacturers and Suppliers.

Several trends are shaping the future development of silicon carbide abrasives and will affect how German and international Silicon Carbide Sanding Manufacturers and Suppliers innovate. Among the most important are:

- Advanced materials: Growth in ceramics, composites and superalloys increases demand for abrasives capable of handling hard‑to‑machine materials, where SiC often excels.

- Automation and digitalization: CNC grinding, robotic sanding and inline measurement demand highly consistent abrasives whose behavior can be predicted and modeled.

- Sustainability: Pressure to reduce waste and energy use is driving development of longer‑life products, recyclable backings and more efficient production technologies.

Silicon carbide abrasive producers that invest in these areas will be better positioned to supply next‑generation components for electric vehicles, renewable energy systems, electronics and precision engineering.

For companies like Dragon Abrasives Group Limited and for German Silicon Carbide Sanding Manufacturers and Suppliers, rich visual material significantly enhances marketing and buyer education. Effective content might include:

- Detailed close‑up images of silicon carbide grinding wheels, sanding belts and waterproof papers showing grain structure and bonding.

- Process photos highlighting before‑and‑after surfaces on glass, stone, metal and composites after SiC sanding and polishing.

- Inside‑factory visuals of mixing, pressing, firing and coating lines to emphasize quality controls and manufacturing scale.

- Short explainer videos demonstrating how to choose grit sizes, backing types and operating parameters for different applications.

- Comparison clips that show performance differences between silicon carbide and other abrasives in controlled tests.

Such materials help purchasers better understand the capabilities of silicon carbide abrasives and the strengths of specific Silicon Carbide Sanding Manufacturers and Suppliers.

Germany remains a strategic hub for silicon carbide abrasives, with established companies offering advanced grinding wheels, sanding products and specialty solutions for industries that demand precision, consistency and reliability. Their strong engineering base, quality systems and application know‑how make German silicon carbide abrasive manufacturers and suppliers attractive partners for high‑value projects in automotive, glass, stone, electronics and many other sectors.

At the same time, global partners such as Dragon Abrasives Group Limited in China complement this ecosystem by supplying high‑quality silicon carbide grains, bonded tools and coated abrasives to Silicon Carbide Sanding Manufacturers and Suppliers worldwide. By integrating German expertise with Chinese manufacturing scale, international buyers can secure competitive pricing, stable quality and robust technical support for all their sanding, grinding and polishing needs.

Silicon carbide is harder and sharper than aluminum oxide, allowing it to cut faster and produce finer finishes on hard or brittle materials. This makes it especially suitable for glass, stone, ceramics and non‑ferrous metals, where traditional abrasives can glaze or smear. For many critical finishing tasks, users rely on Silicon Carbide Sanding Manufacturers and Suppliers to deliver superior results compared with standard aluminum oxide products.

Yes. German silicon carbide abrasive manufacturers and suppliers are used extensively in high‑volume automotive, engineering and construction component production. Their products are designed for stable performance, long life and consistent quality, making them ideal for automated grinding and sanding lines that run multiple shifts and require minimal unplanned downtime.

Overseas buyers can source key, branded silicon carbide grinding wheels or specialty sanding products from German Silicon Carbide Sanding Manufacturers and Suppliers, while working with Dragon Abrasives Group Limited for bulk silicon carbide grains, OEM tools and private‑label sanding products. This combined approach balances premium performance and brand recognition with optimized cost and flexible capacity.

Important factors include detailed product specifications, grit size distribution, backing and bond systems, as well as documented performance tests relevant to the buyer's processes. In addition, purchasers should evaluate the supplier's quality certifications, technical support capabilities, responsiveness, and long‑term delivery reliability, especially when working with Silicon Carbide Sanding Manufacturers and Suppliers for OEM projects.

Many silicon carbide sanding papers, belts and discs are designed for both wet and dry operations, using waterproof backings and resin systems that resist degradation in contact with coolant or water. Users frequently select these versatile products from Silicon Carbide Sanding Manufacturers and Suppliers to improve cooling, minimize clogging and extend tool life, particularly when finishing sensitive surfaces or high‑value components.

Top Pure Silicon Carbide Manufacturers and Suppliers in Russia

Top Pure Silicon Carbide Manufacturers and Suppliers in France

Top Pure Silicon Carbide Manufacturers and Suppliers in Arabia

Top Polishing Silicon Carbide Manufacturers and Suppliers in Thailand

Top Polishing Silicon Carbide Manufacturers and Suppliers in Turkey

Top Polishing Silicon Carbide Manufacturers and Suppliers in Vietnam

Top Polishing Silicon Carbide Manufacturers and Suppliers in South Korea

Top Polishing Silicon Carbide Manufacturers and Suppliers in Japan

Top Polishing Silicon Carbide Manufacturers and Suppliers in Poland

Top Polishing Silicon Carbide Manufacturers and Suppliers in Portugal