Views: 222 Author: Wendy Publish Time: 2025-11-21 Origin: Site

Content Menu

● Understanding Green Silicon Carbide

>> Key Physical and Chemical Properties

● Vietnam's Growth in Green Silicon Carbide Manufacturing

>> Government and Industry Synergy

● Leading Green Silicon Carbide Manufacturers and Exporters

>> VietCarb Materials Co., Ltd

● Manufacturing Process of Green Silicon Carbide in Vietnam

● Main Applications of Green Silicon Carbide

● Market Trends and Future Development

● Sourcing and Supplier Selection in Vietnam

● FAQ: Green Silicon Carbide in Vietnam

>> 1.What are the main differences between Green and Black Silicon Carbide?

>> 2.How is Green Silicon Carbide produced in Vietnam?

>> 3.Are Vietnamese Green Silicon Carbide manufacturers internationally certified?

>> 4.What industrial sectors benefit the most from Vietnamese Green Silicon Carbide?

>> 5.What environmental measures are being adopted in SiC production?

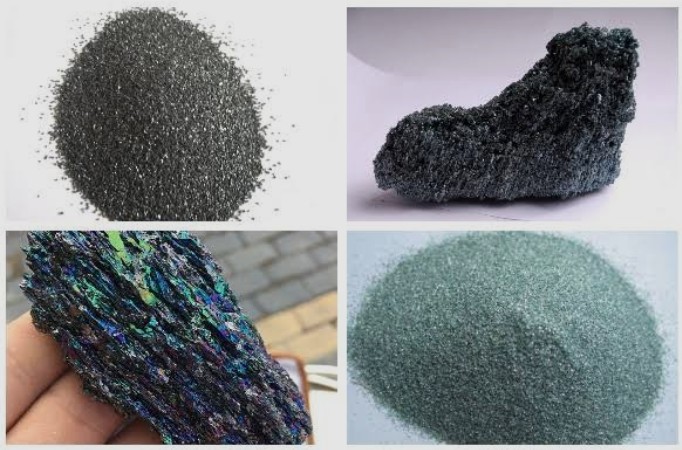

Green Silicon Carbide (SiC) is a prized industrial material known for its extraordinary hardness, thermal stability, and chemical resistance. With Vietnam's accelerating growth in advanced manufacturing and export-oriented industries, the country has become a strategic hub for producing Green Silicon Carbide. This article provides a comprehensive overview of the Top Green Silicon Carbide manufacturers and suppliers in Vietnam, highlighting its manufacturing processes, technological innovations, market dynamics, and the most competitive suppliers serving the global abrasive, refractory, and semiconductor fields.

![]()

Green Silicon Carbide is synthetically produced through the high-temperature reaction of quartz sand (silica) and petroleum coke in resistance furnaces—often with salt as a catalyst. The process yields crystalline silicon carbide, exhibiting a green hue due to its high purity and specific crystal structure.

- Hardness: Green Silicon Carbide ranks immediately below diamond on the Mohs scale, making it ideal for precision grinding and cutting.

- Thermal Conductivity: It efficiently dissipates heat, essential for high-power electronics and refractory applications.

- Chemical Resistance: The material is stable against acids, alkalis, and oxidizing environments, broadening its industrial usability.

- Grain Sharpness: Its acute crystal edges deliver superior grinding efficiency in abrasives.

These attributes make Green Silicon Carbide extensively used in the manufacturing of abrasive wheels, cutting tools, electronic substrates, and high-temperature ceramics.

Vietnam's success in Green Silicon Carbide production draws on several local advantages:

- Abundant Raw Materials: High-purity quartz and energy sources are widely available.

- Technological Adoption: Modern furnace technologies, purification systems, and automation drive product consistency.

- Labor and Costs: Competitive labor costs enable Vietnamese suppliers to offer globally competitive pricing.

- Export Infrastructure: Proximity to major Asian markets and expanded port facilities ensures efficient international logistics.

The Vietnamese government supports high-tech manufacturing through incentives, environmental regulations, and policy alignment with international standards. This has prompted both foreign direct investment and domestic industrial expertise to converge, particularly in the semiconductor and abrasives sectors.[2][3][4][6]

VietCarb Materials is known for its high-purity Green Silicon Carbide, serving solar panel makers, optics firms, and wafer manufacturers. As demand for wafer slicing grits and ultra-fine polishing powders grows, VietCarb continuously upgrades its purification and microgrinding technologies to deliver 99.5% SiC microgrits. The company's consistent quality and robust international certifications make it a preferred supplier for Japan, Germany, Taiwan, and beyond.

VN Abrasive offers an extensive range of Green Silicon Carbide grains and micro powders for applications from precision grinding wheels to refractory ceramics. Their investment in automated crushing and particle size sorting systems enables tailored supply for buyers seeking consistent performance and specialized sizes. VN Abrasive's export markets span Europe, South Korea, and the Middle East.

Specializing in silicon carbide-based refractory products, Asia Refratech manufactures SiC bricks, crucibles, and specialized kiln furniture. Their integrated production—from domestic smelters to finished goods—supports cost-effective solutions for steelmaking, non-ferrous casting, and high-temperature furnaces. As more industries demand environmentally friendly and high-strength refractory materials, Asia Refratech's offerings meet rigorous global standards.

Carbotec pioneers both Black and Green Silicon Carbide manufacturing, with advanced sorting, purification, and testing capabilities. Their products are trusted in abrasive tool fabrication and electronics polishing, benefiting from precise grit grading and low carbon content for consistent and stable chemical properties.

For ultra-fine Green Silicon Carbide powders (submicron to 20 µm), Vina Materials Technology applies jet milling and advanced classification. Their output is integral for semiconductor wafer lapping and LED substrate polishing, where particle purity and consistency are paramount.

Vietnamese manufacturers mostly rely on the Acheson process—an enduring technique since the 19th century—with advances in furnace design and purification. The process proceeds as follows:[1][5][7]

1. Raw Material Selection: High-purity quartz sand and low-ash petroleum coke are prepared, sometimes with salt as a flux to improve yield.

2. Carbothermal Reduction: These materials are mixed and loaded into electric resistance furnaces, then heated to about 2200°C. The reaction forms SiC crystals, releasing waste gases and forming ingots.

3. Cooling and Extraction: Upon cooling, silicon carbide ingots are extracted, with excess free carbon and silicon separated.

4. Purification: Pickling and chemical leaching are applied to remove impurities, followed by mechanical crushing.

5. Classification: The crushed SiC is sieved, milled, and classified into microgrits or powders of defined size ranges.

6. Quality Assurance: Particle size distribution, purity, and hardness tests are conducted per FEPA/JIS standards and ISO certifications.

Newer processes being piloted in Vietnam include the use of recycled silicon waste and methane/biogas to lower environmental impact and production costs. Controlled atmosphere furnaces and smart manufacturing systems reduce toxic emissions and enhance yield, positioning Vietnam favorably in the shift toward greener silicon carbide technologies.[5][2]

![]()

Green Silicon Carbide's versatility drives its use in an expanding array of industrial applications:

- Abrasives: High-purity grains are critical for manufacturing grinding wheels, polishing pads, lapping mediums, and precise cutting discs.

- Refractories: SiC imparts excellent resistance to wear and thermal shock in kiln furniture, crucibles, bricks, and foundry linings.

- Semiconductors: Electronic-grade Green SiC wafers serve as substrates in power devices, LEDs, photovoltaic cells, and high-frequency switches.

- Metalworking and Precision Polishing: Its hardness and sharpness allow for precision polishing of glass, ceramics, and non-ferrous metals, central to optics and electronics.

- Chemical and Environmental Industries: Composite SiC products are used in chemical reactors, filters, and mechanical seals owing to their corrosion resistance.

Demand for Green Silicon Carbide in Vietnam continues to rise due to several intertwined trends:

- Technological Upgrading: Foreign direct investment and partnerships, such as those led by global semiconductor giants, catalyze R&D, process innovation, and scaling of SiC production.[3][4][6]

- Supply Chain Resilience: The establishment of advanced SiC fabs and slicing/polishing plants, coupled with investment in local parks, strengthens the export capacity and market reach of Vietnamese suppliers.

- Regulatory and Environmental Compliance: Producers increasingly align with ISO, RoHS, and REACH standards, supporting eco-conscious buyers and international quality demands.

- Expanding End-User Markets: Rapid growth in renewable energy, electric vehicles, and digital infrastructure is expanding SiC's use in power electronics and high-temperature applications.

Vietnam's continued investment in infrastructure, environmental management, and skilled labor promises ongoing growth as a global hub for Green Silicon Carbide.

Buyers seeking Green Silicon Carbide from Vietnam benefit from:

- Stable Supply Chains: Investments in capacity and logistics minimize disruptions—even during global uncertainties.

- Flexibility for Customization: Vietnamese suppliers offer a wide range of grit sizes, grades, and custom packaging for specialized industry needs.

- Technical and OEM Support: Leading manufacturers provide material optimization advice, application consulting, and private labeling for international partners.

- Competitive Pricing: Lower operating costs mean value for buyers without sacrificing performance.

When evaluating a Vietnamese SiC supplier, consider their technical certifications (ISO 9001, ISO 14001), production capacity, export record, and ability to offer product customization for your application.

Vietnam's emergence as a leading producer and exporter of Green Silicon Carbide reflects strategic investment in technology, quality, and global trade connectivity. The country's manufacturers deliver high-purity, competitively priced SiC for abrasives, refractories, and semiconductor applications. By partnering with Vietnamese suppliers, businesses can optimize supply chain resilience, reduce costs, and access advanced material technology.

Green Silicon Carbide is purer, sharper, and harder than Black Silicon Carbide. It is primarily used in precision applications like glass grinding, wafer slicing, and ceramics polishing, whereas Black SiC is better suited to metal grinding and coarser abrasive uses.

Most Vietnamese suppliers utilize the Acheson process, combining high-purity quartz and petroleum coke in electric resistance furnaces, followed by purification, crushing, and particle sizing.

Reputable Vietnamese manufacturers often hold ISO 9001 and ISO 14001 certifications for quality and environmental management, as well as comply with FEPA/JIS grit sizing and RoHS/REACH safety standards.

Abrasive tool manufacturers, refractory product companies, semiconductor and electronics producers, optics and solar cell industries all benefit from Vietnam's supply of high-purity, customizable Green SiC.

Vietnamese producers increasingly focus on emissions control, recycling, and modernization of furnace technologies to comply with international standards and support the shift toward greener industrial production.

[1](https://onlinelibrary.wiley.com/doi/abs/10.1002/vjch.202000043)

[2](https://www.linkedin.com/pulse/vietnam-silicon-carbide-sic-semiconductor-amyvf)

[3](https://www.trendforce.com/news/2025/08/06/news-coherent-opened-up-a-new-sic-fab-in-vietnam/)

[4](https://compoundsemiconductor.net/article/122256/Coherent_opens_SiC_facility_in_Vietnam)

[5](https://www.aiche.org/resources/publications/cep/2022/october/catalyzing-commercialization-novel-low-cost-sustainable-process-produce-silicon-carbide)

[6](https://en.vneconomy.vn/coherent-inaugurates-127mln-semiconductor-plant-in-dong-nai.htm)

[7](https://greensiliconcarbide.com/high-quality-green-silicon-carbide/)

Top Pure Silicon Carbide Manufacturers and Suppliers in Russia

Top Pure Silicon Carbide Manufacturers and Suppliers in France

Top Pure Silicon Carbide Manufacturers and Suppliers in Arabia

Top Polishing Silicon Carbide Manufacturers and Suppliers in Thailand

Top Polishing Silicon Carbide Manufacturers and Suppliers in Turkey

Top Polishing Silicon Carbide Manufacturers and Suppliers in Vietnam

Top Polishing Silicon Carbide Manufacturers and Suppliers in South Korea

Top Polishing Silicon Carbide Manufacturers and Suppliers in Japan

Top Polishing Silicon Carbide Manufacturers and Suppliers in Poland

Top Polishing Silicon Carbide Manufacturers and Suppliers in Portugal