Views: 222 Author: Lake Publish Time: 2025-03-25 Origin: Site

Content Menu

● What is Glass Bead Sandblasting?

● Benefits of Glass Bead Sandblasting

● Is Glass Bead Sandblasting Media Safe?

● Applications of Glass Bead Sandblasting

● Materials Suitable for Glass Bead Sandblasting

● How to Choose the Right Glass Beads

● Best Practices for Glass Bead Sandblasting

● Alternatives to Glass Bead Sandblasting

● FAQ

>> 1. Is glass bead blasting safe for all types of metal?

>> 2. Can glass bead blasting remove coatings like powder coating?

>> 3. How many times can glass beads be reused?

>> 4. What safety precautions should I take when using glass bead blasting media?

>> 5. Is glass bead blasting environmentally friendly?

Sandblasting is a versatile method for surface preparation and finishing across various industries[6]. Among the different media utilized in sandblasting, glass bead sandblasting media is recognized for its unique characteristics and broad applications[6]. This article explores the safety and applications of glass bead sandblasting media on different surfaces, its benefits, and best practices.

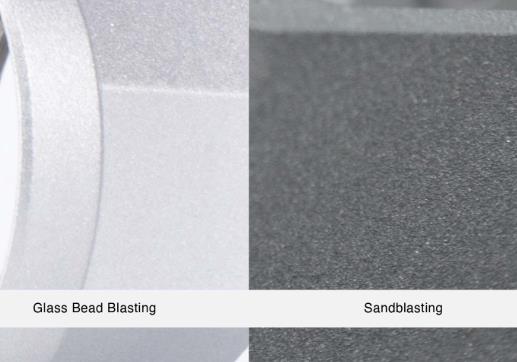

Sandblasting, also known as abrasive blasting, involves propelling abrasive media against a surface to clean, smooth, or prepare it[6]. Glass bead sandblasting uses small, spherical glass beads made from high-quality glass[6]. These glass beads come in various sizes and grades, allowing precise control over the blasting process[6]. The spherical shape of glass beads ensures a uniform finish without damaging the underlying material[6].

Glass bead sandblasting offers several advantages that make it a preferred choice in many industries[10]:

- Surface Cleaning: Glass beads effectively remove rust, paint, and other contaminants from metal surfaces without causing pitting or damage[6].

- Surface Preparation: Before applying coatings like paint or powder coating, glass beads create a clean, slightly roughened surface, enhancing adhesion[6].

- Gentle on Surfaces: The non-abrasive nature of glass beads preserves the original surface, making them suitable for delicate and sensitive materials[10].

- Uniform Finish: Glass beads provide a consistent and smooth finish, ideal for applications requiring high-quality surface aesthetics[5].

- Reusability: High-quality glass beads can be reused multiple times, offering cost-effectiveness and environmental benefits[2][10].

- Minimal Dust Production: Glass beads produce minimal dust, enhancing workplace safety and reducing environmental impact[3][10].

- Chemically Inert: Glass beads are chemically inert, ensuring no reactions occur with the materials being treated[2].

- Environmentally Friendly: Typically made from recycled glass, glass beads lower the carbon footprint[2].

Glass bead sandblasting media is generally considered safe for sandblasting[1]. It is a popular choice for surface cleaning and preparation because it is environmentally friendly, non-toxic, and inert[1][2]. Unlike silica sand, glass beads do not contain free silica, reducing concerns over long-term health effects, particularly on the respiratory system[2].

However, safety precautions are still necessary:

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including a respirator/dust mask, to avoid inhaling dust particles[1][7].

- Ventilation: Work in a well-ventilated area to minimize dust exposure[1].

- Equipment Maintenance: Regularly inspect hoses, couplings, the blasting unit, and the air compressor for wear, leaks, or damage[3].

- Safe Practices: Maintain a safe working distance from the work surface and never point the nozzle at yourself or others[3].

Glass bead sandblasting is versatile and used across various industries[6]:

- Automotive Industry: Removing rust and paint, preparing surfaces for painting, and cleaning engine parts[5][6].

- Aerospace Industry: Cleaning and maintaining aircraft components without altering their dimensions[5].

- Medical Industry: Finishing medical implants and devices due to its non-reactive properties[2].

- Plastic and Rubber Industries: Cleaning molds to ensure a smooth, clean surface for the next production cycle[6].

- Electronics Industry: Preparing circuit boards for soldering[5].

- Metal Fabrication: Cleaning weld seams and preparing surfaces for further processing or inspection[6].

- Decorative Applications: Creating smooth, satin, or matte finishes on decorative metals[5].

Glass bead sandblasting is suitable for a wide range of materials due to its gentle abrasive action[3]:

- Metals: Including aluminum, steel, stainless steel, and alloys[6].

- Plastics: Certain types of plastics that are not easily damaged by the impact[10].

- Glass: For creating etched or frosted effects[9].

- Rubber: Cleaning molds and preparing surfaces[6].

- Composites: Preparing composite materials for bonding or coating[5].

Selecting the appropriate glass beads depends on the specific application and desired finish[5]:

- Size: Finer glass beads are used for polishing and creating smooth finishes, while coarser glass beads are used for more aggressive cleaning and surface preparation[11].

- Grade: High-quality glass beads ensure consistent performance and reduce the risk of contamination[6].

- Hardness: The hardness of glass beads should be appropriate for the material being treated to avoid damage[11].

To achieve the best results with glass bead sandblasting, follow these best practices[3]:

- Pre-Operation Inspection: Regularly check equipment for wear and damage[3].

- Consistent Technique: Maintain a consistent distance and angle between the nozzle and the workpiece for even blasting[3].

- Proper Pressure: Gradually increase pressure and media flow to the minimum needed for the desired result[3].

- Clean-Up: Use HEPA-filtered vacuums to clean up fine dust particles[3].

- Media Disposal: Dispose of used blasting media according to local regulations and the media's Safety Data Sheet (SDS)[3].

While glass bead sandblasting is suitable for many applications, other abrasive media may be more appropriate for specific tasks[4]:

- Aluminum Oxide: Highly abrasive and suitable for etching and removing tough coatings[4].

- Steel Shot: Used for heavy-duty applications like de-rusting and shot peening[11].

- Plastic Media: Less aggressive and suitable for delicate surfaces but may not achieve the same level of finish as glass beads[10].

- Garnet: Suitable for surface etching and preparing surfaces for coating[11].

Glass bead sandblasting media is a safe, versatile, and effective option for various surface treatment applications[1][5]. Its non-toxic nature, combined with its ability to deliver a consistent, smooth finish, makes it a preferred choice across numerous industries[2][6]. By following proper safety precautions and best practices, glass bead sandblasting can provide superior results while minimizing health and environmental risks[3]. Understanding its benefits, limitations, and appropriate applications ensures that glass bead sandblasting remains a valuable technique for surface preparation and finishing[5][6].

Glass bead blasting is generally safe for most metals, including aluminum, steel, and stainless steel[6]. However, it's essential to adjust the pressure and bead size to prevent any damage to softer metals. For extremely delicate metals, testing a small, inconspicuous area first is recommended.

Yes, glass bead blasting can remove coatings like powder coating, but it may require more aggressive blasting techniques with coarser glass beads and higher pressure[6]. For heavy coatings, other media like aluminum oxide might be more efficient[4].

Glass beads can typically be reused multiple times, often up to 4-6 cycles, depending on the application and the quality of the glass beads[2]. Regularly inspect the beads for any signs of wear or contamination, and replace them as needed to maintain consistent results. Some sources claim glass beads can be reused up to 30 times[11].

Always wear appropriate personal protective equipment (PPE), including a respirator, safety goggles, and gloves[1]. Ensure the blasting area is well-ventilated to minimize dust exposure[1]. Regularly inspect and maintain your equipment, and follow the manufacturer's instructions for safe operation[3].

Glass bead blasting is considered environmentally friendly because glass beads are typically made from recycled glass and are chemically inert[2]. They also produce minimal dust compared to other blasting media, reducing environmental impact[3][10]. Proper disposal of used glass beads according to local regulations is essential.

[1] https://www.kramerindustriesonline.com/glass-media-differences-crushed-glass-vs-glass-beads/

[2] https://www.kuegroup.com/the-benefits-of-using-glass-bead-as-an-abrasive-in-your-blasting-project/

[3] https://www.unionfab.com/blog/2024/06/bead-blasting

[4] https://www.youtube.com/watch?v=Oee5tozB850

[5] https://vibra.com/glass-bead-blasting/

[6] https://www.tenroadsglass.com/the-ultimate-guide-to-sand-blasting-glass-beads-applications-and-benefits/

[7] https://forum.caswellplating.com/forum/other-metal-finishing-questions/1072-does-glass-bead-cause-silicosis-or-is-it-harmful

[8] https://pittsburghsprayequip.com/blogs/pittsburgh-spray-equipment-company/glass-bead-blasting-pros-cons-common-uses-equipment-needed

[9] https://www.youtube.com/watch?v=HmgzS_0QmB4

[10] https://www.tenroadsglass.com/comparing-blasting-media-why-glass-beads-stand-out.html

[11] https://www.xometry.com/resources/machining/bead-blasting-guide/

[12] https://www.glassblast.com/faq/

[13] https://www.osha.gov/sites/default/files/publications/OSHA3697.pdf

[14] https://www.blastone.com/understanding-glass-media-as-a-blasting-abrasive/

[15] https://www.airblasteurospraydirect.com/blog/sandblasting-vs-glass-bead-blasting-whats-the-difference/

[16] https://www.balotinovani.com/en/bead-blasting

[17] https://www.kramerindustriesonline.com/product/glass-beads/

[18] https://www.youtube.com/watch?v=9Qlt_ggR5ag

[19] https://knifedogs.com/threads/bead-blasting-media-questions-opinions.8312/

[20] https://www.bladeforums.com/threads/bead-blasting-question.644319/

[21] https://www.reddit.com/r/Skookum/comments/a0ys0e/advice_on_sandblasting_and_general_breathing/

[22] https://www.burwell.com.au/assets/volumes/downloads/SDS_Glass-Bead-Blasting-Media.pdf

[23] https://www.finishingsystems.com/blog/4-necessary-precautions-for-keeping-sandblasting-safe/

[24] https://www.kramerindustriesonline.com/safety-practices-when-using-aluminum-oxide-media-in-sandblasting/

[25] https://www.grizzly.com/products/grizzly-sandblasting-media-glass-bead-50-micron-15-lbs./g6538

[26] https://www.sandblasters.co.uk/glass-bead-coarse-glass-blasting-media-1351-p.asp

[27] https://www.giantfinishing.com/listings/2551672-glass-bead-blasting-media-8

[28] https://www.youtube.com/watch?v=7FzRRSf7gBY

[29] https://www.practicalmachinist.com/forum/threads/surface-finish-question-when-blasting-with-glass-beads.255081/

Top Pure Silicon Carbide Manufacturers and Suppliers in Russia

Top Pure Silicon Carbide Manufacturers and Suppliers in France

Top Pure Silicon Carbide Manufacturers and Suppliers in Arabia

Top Polishing Silicon Carbide Manufacturers and Suppliers in Thailand

Top Polishing Silicon Carbide Manufacturers and Suppliers in Turkey

Top Polishing Silicon Carbide Manufacturers and Suppliers in Vietnam

Top Polishing Silicon Carbide Manufacturers and Suppliers in South Korea

Top Polishing Silicon Carbide Manufacturers and Suppliers in Japan

Top Polishing Silicon Carbide Manufacturers and Suppliers in Poland

Top Polishing Silicon Carbide Manufacturers and Suppliers in Portugal